12

M1.2.ME15W-ME20W.NLFREN 30032018

EN

MACH

2 Description of the machine

2.1 General description

A. Eye protection shields

B. Workpiece bearing plate

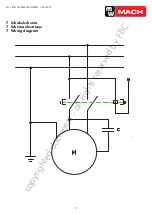

C.

ON/OFF switch

D. Eye protections shields brackets

E. Wheel cover

F. Plug

2.2 Technical data

Model

ME15W

ME20W

Voltage

230 V

230 V

Motor power

520 W

900 W

Grinding wheel dimensions (Ø x base x Ø shaft hole)

150 x 25 x 32 mm

200 x 32 x 32 mm

Brush dimensions (Ø x base x Ø shaft hole)

150 x 25 x 32 mm

200 x 32 x 32 mm

Speed

2950 min

-1

2950 min

-1

Machine weight

15 kg

27 kg

Machine dimensions (l x w x h)

550 x 261 x 254 mm

596 x 320 x 310 mm

3 Installation

3.1 Site requirements

In order to provide for good functionality and high machining accuracy as well as a long durability of the machine, the site

should fulfil following criteria :

• The machine must be installed in a dry and well ventilated place.

• Avoid places with machines generating harmful chips or dust.

• Avoid place with machines generating vibrations such as planing machines, presses, etc.

• The machine should be installed on an even and horizontal surface.

• Protruding parts (stops, handles, etc.) need to be secured to avoid danger for persons.

•

Provide sufficient space for assembly, operating and servicing.

•

Provide sufficient lighting (minimum 500 lux). If necessary, provide additional lighting.

• The access to the power plug must be kept free.

• For 400 V machines:

Imperatively make sure that all 3 phases (L1, L2, L3) are connected correctly. Most of the defects on motors are resulting

from wrong connections. For instance, if a motor phase is not correctly clamped or connected to the neutral conductor (N).

This may cause:

- That the motor becomes hot very rapidly.

- That the motor noises increase.

- That the motor has no power.

A wrong connection of the machine invalidates the guarantee.

3.2 Assembly

1. Assemble the eye shields, spark breakers and workpiece bearing plates using the screws, etc. provided.

2. Make sure there is not more than 1/6’’ (1.6 mm) between those items and the edge of the grinding wheel.

3. It is advisable to secure the bench grinder to the workbench or stand.

copyrighted

document

- all

rights

reserved

by

FBC