29

M1.2.TPT820.NLFREN 21112017

EN

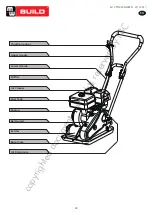

Fuel valve control

The fuel valve opens and closes the passage between the fuel tank and the carburetor. The fuel valve lever must be in the ON

position for the engine to run. When the engine is not in use, leave the fuel valve lever in the OFF position to prevent carburetor

flooding and to reduce the possibility of fuel leakage.

Throttle control

The throttle lever controls engine speed. Moving the throttle lever in the directions shown makes the engine run faster or slower.

Engine switch

The engine switch enables and disables the ignition system.

The engine switch must be in the ON position for the engine to run.

Turning the engine switch to the OFF position stops the engine.

Choke lever

The choke lever opens and closes the choke valve in the carburetor. The closed position enriches the fuel mixture for starting a

cold engine. The open position provides the correct fuel mixture for operation after starting, and for restarting a warm engine.

Some engine applications use a remotely-mounted choke control rather than the engine-mounted choke lever.

Recoil starter grip

Pulling the starter grip operates the recoil starter to crank the engine.

Belt guard

Remove this guard to gain access to the V-belt. Never run the compactor without the V-belt guard. If the V-belt guard is not

installed, the possibility exists that your hand may get caught between the V-belt and clutch, thus causing serious injury and

bodily harm.

Exciter

An eccentric weight mounted on the exciter shaft contained within exciter housing is driven at high speed by a clutch and belt

drive system. This high speed shaft revolution causes the rapid lifting and downward ramming motion of the machine as well as

imparting a forward motion.

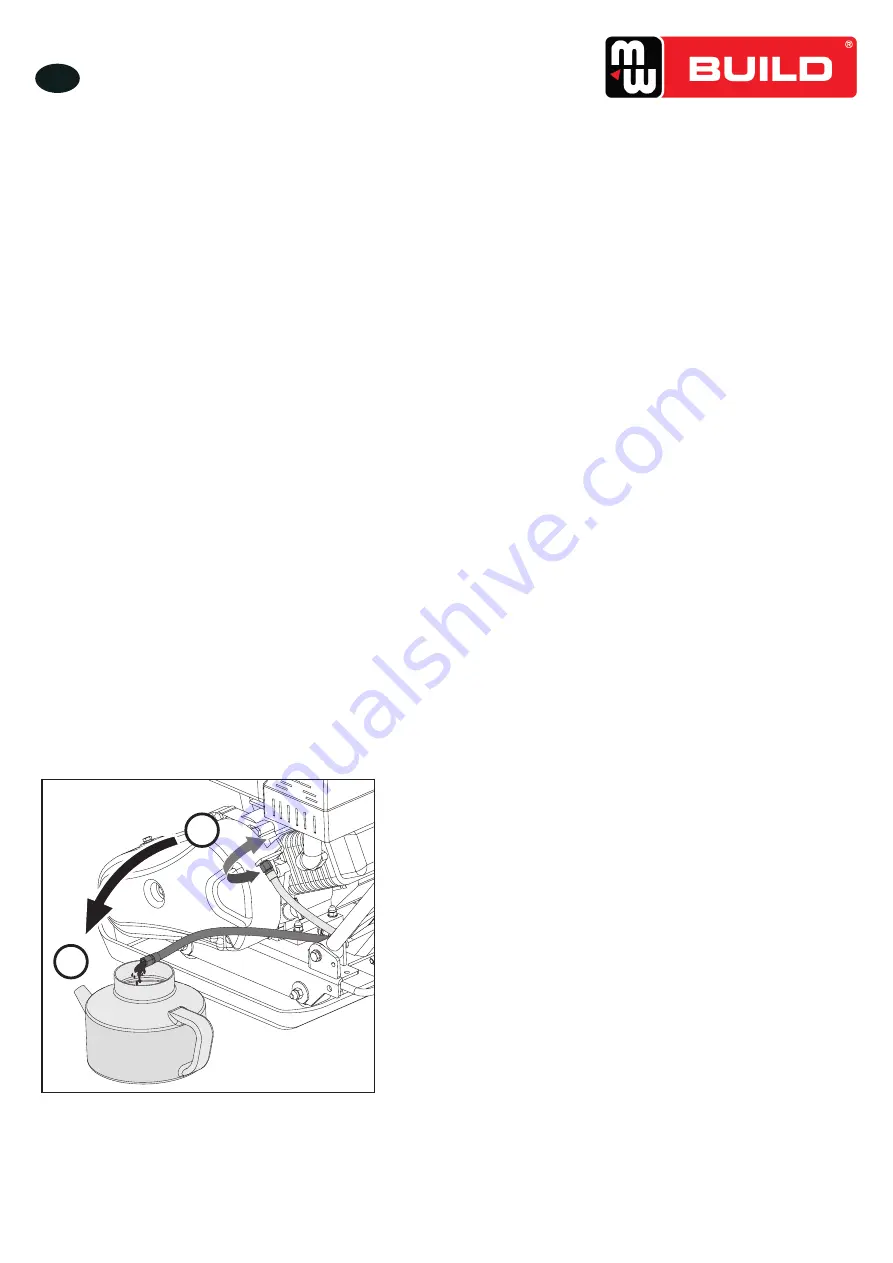

Oil drain hose

Running the engine with dirty oil can cause premature engine wear and failure. Changing oil regularly is extremely important.

The flexible oil drain hose is equipped to drain oil into appropriate receptacle.

Compactor Operation

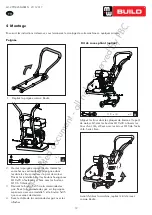

Adding fuel

Fill the fuel tank as instructed in the separate

Engine Manual

packed with the Plate Compactor.

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke to the

CLOSE position.

To restart a warm engine, leave the choke lever

in the OPEN position.

3. Move the throttle lever away from the SLOW

position, about 1/3 of the way toward the FAST

position.

4. Turn the engine switch to the ON position.

5. Operate the starter.

If the choke lever has been moved to the CLOSE

position to start the engine, gradually move it to

the open position as the engine warms up.

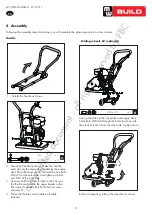

Operating

Starting engine

The open position provides the correct fuel mixture

for operation after starting, and for restarting a

warm engine. Some engine applications use a

remotely-mounted choke control rather than the

engine-mounted choke lever.

Recoil Starter Grip

Pulling the starter grip operates the recoil starter

to crank the engine.

More detailed description of the engine operation and

all related precautions and procedures can be found

in the

Engine Manual

packed separately with the unit.

9

Vibratory Plate Compactor

Pull the starter grip lightly until you feel resistance,

then pull briskly, return the starter grip gently.

Recoil Starter

Oil Drain Hose

Running the engine with dirty oil can cause

premature engine wear and failure. Changing oil

regularly is extremely important. The

flexible

oil

drain hose is equipped to drain oil into appropriate

receptacle.

After engine warms up, pull throttle lever to

accelerate engine speed. Plate will begin

vibrating and move forward.

The plate compactor is designed to run at an

engine speed (engine take off shaft) of 3600

rpm (Normally considered full throttle). Running

the engine at lower rpm’s will result in a decrease

of compaction force and lower travel speed. It

will create excessive “out-of-synch” vibrations

resulting in poor compaction, maneuverability,

excessive wear to the machine, and discomfort

to the operator.

In operation, guide the machine, but let the

compactor do the work. Bearing down on the

handle is unnecessary and causes shock

absorber wear.

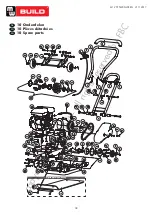

1.

2.

3.

Exciter

An eccentric weight mounted on the exciter shaft

contained within exciter housing is driven at high

speed by a clutch and belt drive system. This high

speed shaft revolution causes the rapid lifting and

downward ramming motion of the machine as well

as imparting a forward motion.

Do not operate plate on concrete or

on extremely hard, dry, compacted

surfaces. The plate will jump rather

than vibrate and could damage both

plate and engine.

1

2

copyrighted

document

- all

rights

reserved

by

FBC