34

M1.2.TPT820.NLFREN 21112017

EN

When adjusting the belt, make sure that the clutch pulley is in alignment with exciter pulley.

4. When the V-belt tension is correct, tighten the jam nuts B against the bracket.

5. Tighten the engine mount bolts.

6. Replace the belt guard.

If the adjustment bolts have no more adjustment left, the belt may have to be replaced.

7 Maintenance

Maintaining your compactor will insure long life to the machine and its components.

Preventive Maintenance

1. Turn off engine. Engine must be cool.

2. Keep the engine’s throttle lever in its SLOW position, and remove spark plug wire from spark plug and secure.

3. Inspect the general condition of the plate compactor. Check for loose screws, misalignment or binding of moving parts,

cracked or broken parts, and any other condition that may affect its safe operation.

4. Remove all debris from the plate compactor with a soft brush, vacuum, or compressed air. Then use a premium quality

lightweight machine oil to lubricate all moving parts.

5. Clean the bottom of the compactor base as soon as it begins to pick up soil being compacted. The unit can not do a good

job if the bottom surface is not smooth and clean.

6. Replace spark plug wire.

Never use a “pressure washer” to clean your plate compactor. Water can penetrate tight areas

of the unit and cause damage to spindles, pulleys, bearings, or the engine. The use of pressure

washers will result in shortened life and reduce serviceability.

Checking V-belt

To ensure optimum power transmission from the engine to the eccentric shaft, the V-belt must be in good condition and operate

under proper tension.

1. Turn off engine. Engine must be cool.

2. Remove the belt guard to access the V-belt.

3. Check the condition of the V-belt. If any V-belt is cracked, frayed, or glazed, it should be replaced as soon as convenient.

4.

Check the V-belt tension by squeezing them in the center. The normal deflection on each side should be 9 mm (3/8”) to 13

mm (1/2”) with moderate pressure from your thumb or finger.

On new machines or after installing a new belt, check belt tension after first 20 hours of operation. Check and adjust

belt every 50 hours thereafter.

Tensioning V-belt

Proper belt tension is critical to good performance. Proper adjustment will assure long belt life. Too much or too little belt

tension will cause premature belt failure.

1. Loosen 4 engine mount bolts (do not remove) only enough to move the engine forward.

2. Loosen the jam nuts B, leaving enough space

between the nut and bracket.

11

Vibratory Plate Compactor

Turn off engine. Engine must be cool.

Remove the belt guard to access the V-belt(s).

Check the condition of the V-belt(s). If any V-

belt is cracked, frayed, or glazed, it should be

replaced as soon as convenient.

Check the V-belt tension by squeezing them in

the center. The normal deflection on each side

should be 9mm (3/8”) to 13mm (1/2”) with

moderate pressure from your thumb or finger.

1.

2.

3.

4.

Tensioning V-Belt(s)

Loosen 4 engine mount bolts (do not remove)

only enough to move the engine forward.

Proper belt tension is critical to good performance.

Proper adjustment will assure long belt life. Too

much or too little belt tension will cause premature

belt failure.

1.

When the V-belt tension is correct, tighten the

jam nuts

B

against the bracket.

Tighten the engine mount bolts.

Replace the belt guard.

4.

5.

6.

If the adjustment bolts have no more

adjustment left, the belt(s) may have to

be replaced.

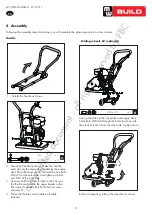

Replacing V-Belt(s)

For #29142 & #29155, both V-belts should

be replaced at the same time because they

will wear evenly through normal use. Work

on one belt at a time.

Loose 4 engine mount bolts (do not remove)

only enough to move the engine forward.

Loosen the jam nuts

B

and bolts

A

shown in

above figure.

Slide the engine toward the front of plate and

slip the old V-belt(s) off of the wheel pulley and

install the new V-belt(s) in their place.

Position the V-belt(s) over the engine pulley.

Move the engine back.

1.

2.

3.

4.

5.

6.

Replace the belt guard.

7.

A

B

On new machines or after installing a

new belt, check belt tension after first

20 hours of operation. Check and adjust

belt every 50 hours thereafter.

When adjusting the belt(s), make sure

that the clutch pulley is in alignment

with exciter pulley.

When adjusting the belt(s), make sure

that the clutch pulley is in alignment

with exciter pulley.

When the V-belt tension is correct, tighten the

jam nuts

B

and the engine mount bolts.

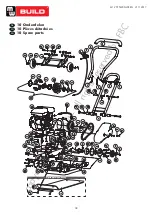

V-belt

Clutch pulley

Exciter pulley

V-belt

Clutch pulley

Exciter pulley

Loosen the jam nuts

B

, leaving enough space

between the nut and bracket.

Push engine toward the back of the plate by

turning the adjustment bolts

A

to remove any

slack in V-belt(s).

2.

3.

11

Vibratory Plate Compactor

Turn off engine. Engine must be cool.

Remove the belt guard to access the V-belt(s).

Check the condition of the V-belt(s). If any V-

belt is cracked, frayed, or glazed, it should be

replaced as soon as convenient.

Check the V-belt tension by squeezing them in

the center. The normal deflection on each side

should be 9mm (3/8”) to 13mm (1/2”) with

moderate pressure from your thumb or finger.

1.

2.

3.

4.

Tensioning V-Belt(s)

Loosen 4 engine mount bolts (do not remove)

only enough to move the engine forward.

Proper belt tension is critical to good performance.

Proper adjustment will assure long belt life. Too

much or too little belt tension will cause premature

belt failure.

1.

When the V-belt tension is correct, tighten the

jam nuts

B

against the bracket.

Tighten the engine mount bolts.

Replace the belt guard.

4.

5.

6.

If the adjustment bolts have no more

adjustment left, the belt(s) may have to

be replaced.

Replacing V-Belt(s)

For #29142 & #29155, both V-belts should

be replaced at the same time because they

will wear evenly through normal use. Work

on one belt at a time.

Loose 4 engine mount bolts (do not remove)

only enough to move the engine forward.

Loosen the jam nuts

B

and bolts

A

shown in

above figure.

Slide the engine toward the front of plate and

slip the old V-belt(s) off of the wheel pulley and

install the new V-belt(s) in their place.

Position the V-belt(s) over the engine pulley.

Move the engine back.

1.

2.

3.

4.

5.

6.

Replace the belt guard.

7.

A

B

On new machines or after installing a

new belt, check belt tension after first

20 hours of operation. Check and adjust

belt every 50 hours thereafter.

When adjusting the belt(s), make sure

that the clutch pulley is in alignment

with exciter pulley.

When adjusting the belt(s), make sure

that the clutch pulley is in alignment

with exciter pulley.

When the V-belt tension is correct, tighten the

jam nuts

B

and the engine mount bolts.

V-belt

Clutch pulley

Exciter pulley

V-belt

Clutch pulley

Exciter pulley

Loosen the jam nuts

B

, leaving enough space

between the nut and bracket.

Push engine toward the back of the plate by

turning the adjustment bolts

A

to remove any

slack in V-belt(s).

2.

3.

3. Push engine toward the back of the plate by turning the adjustment

bolts A to remove any slack in V-belt.

copyrighted

document

- all

rights

reserved

by

FBC