8. FITTING THE MIXER VALVE

IMPORTANT: Ensure that you have read through section 7. IMPORTANT INSTALLATION INFORMATION before

starting to fit the mixer valve.

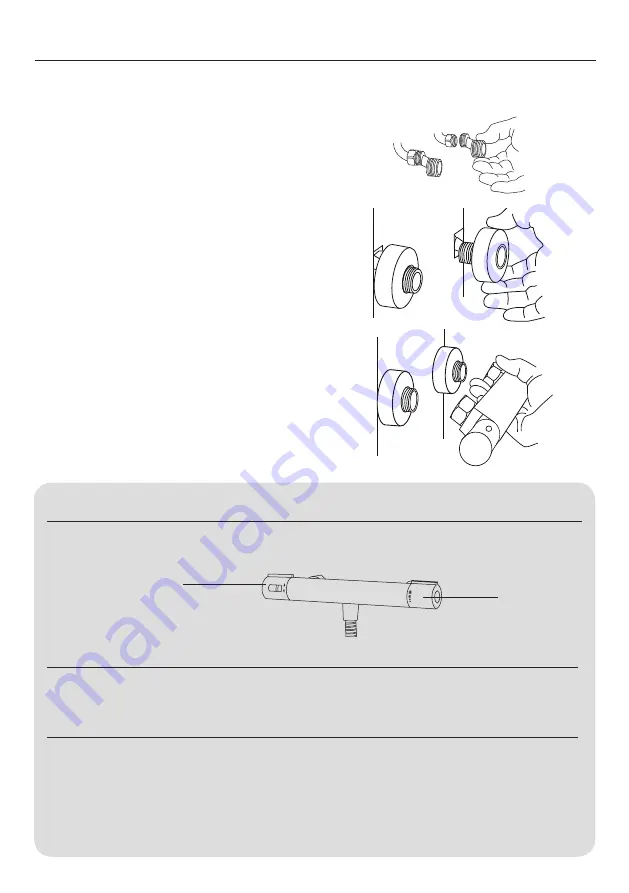

1. The supply pipework can be plumbed from above

or below but must finish with suitable connections,

which should be at 150mm centres. A standard

Easy Fit Kit can be purchased to make installation

easier if required. Connect the 15mm pipework

using standard compression fittings (Fig 1).

2. Screw the supplied nut covers onto the dogleg

fittings until tight to the wall. If required put a bead

of silicone sealant around the inside of the cover to

prevent moisture entering the wall. The nut cover

can be adjusted depending on the length of exposed

thread from the elbow (Fig 2).

3. Offer the mixer valve to the fittings, making sure

the sealing washers are in place, screw the unions

onto the fittings. The mixer valve must be positioned

horizontally with the hot supply on the left hand side

of the outlet (Fig 3).

NOTE: Ensure you have the correct valve with the

water outlet on the bottom when the hot water inlet is

to the left.

1

2

3

9. OPERATION

There are 2 control handles on the mixer valve.

TO CONTROL THE FLOW

Turn the right control handle anti-clockwise to turn on and increase the flow. Turn clockwise to decrease

and turn off.

TO CONTROL THE TEMPERATURE

On the temperature control a numbered dial indicates the direction for hot and cold flow.

Turn anti-clockwise for hot and clockwise for cold.

If in operation an increase in temperature above the factory set temperature is required, simply depress

the stop button on the temperature handle when it reaches the stop and continue to turn the handle

anti-clockwise until the desired temperature is found.

38

• Flow Control

Temperature Control •