32

OPERATING

&

INSTALLATION

INSTRUCTIONS

FOR

INBUILT

WOOD

HEATERS

APPENDIX

1:

BAFFLE

PLATE

LOCATION

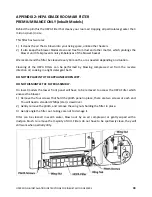

1.

The

baffle

plate

will

need

to

be

removed

for

the

cleaning

of

your

flue

system.

2.

Ensure

the

fire

is

completely

out

before

proceeding.

3.

Remove

firebricks

from

your

firebox.

4.

Lift

baffle

from

injector

rails

at

front

&

rear

of

firebox

and

lower

back

of

baffle

to

the

base

of

the

firebox.

5.

Take

note

of

the

position

of

the

locating

tabs

to

the

side

of

the

baffle

plate,

make

sure

it

goes

in

the

same

way.

6.

Ensure

the

injectors

are

pushed

all

the

way

to

the

right

before

re

‐

installing

the

baffle

plate.

7.

After

cleaning

flue

system

simply

reverse

the

procedure

to

replace

your

baffle

before

relighting

the

fire.

DO

NOT

LIGHT

THE

FIRE

WHILE

THE

BAFFLE

IS

REMOVED

AS

THIS

COULD

CAUSE

A

SERIOUS

HOUSE

FIRE.