6.0 Operation

14

6.6 Adjusting the Knife Depth

The depth of cut can be adjusted using the knife depth adjusting screw located on the left side of the

machine. The same T-handled wrench used for changing the knife can be used to adjust the screw.

Turn the screw counter-clockwise to increase knife depth, and clockwise to decrease knife depth. It

is better to make several slight adjustments and perform test cuts in between, than to make large

adjustments and cut too deep. Try to avoid setting the knife too deep because this can cause

premature wear on knife and/or damage the cut stick.

Figure 10 – Knife Depth Adjustment

6.7 Operating Tips

Carefully lay out each sheet before you start cutting. Find the best cut pattern to give you the most

pieces out of the sheet. If the sheet will be folded, be sure grain of the paper is running in the same

direction as the fold or you will get a rough edge on the fold.

If an accurate cut is necessary for close register work, you MUST have a sharp blade in the cutter. A

dull blade will pull or draw the paper and cause uneven cutting. Increased clamp pressure will not

eliminate draw caused by a dull knife.

The correct clamping pressure varies from paper to paper. The general rule is that you should have

enough pressure to hold the paper securely but not so much that it marks the surface of the paper

excessively. Excessive pressure causes pile distortion and inaccurate cuts.

Mark the gripper edge and the guide edge of printed paper and make sure the first cuts are with these

guide edges against the backgauge.

When cutting business cards or narrow strips of paper, place lifts of equal height on opposite sides of

the table to provide better clamping.

Knife Adjusting

Screw

Summary of Contents for Challenge Spartan 150M

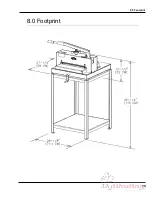

Page 20: ...8 0 Footprint 19 8 0 Footprint...