7.0 Knife Installation/Changing

16

3. With the knife at its extreme up position, lift the hood.

4. Remove the two knife bolts that are mounted in open slots in the knife bar.

5. Install the knife lifter onto the knife holder. Screw the handles into the holes from which the

two, knife bolts were removed. Firmly tighten each handle.

6. Remove the remaining knife bolts.

7. Place an empty knife scabbard on a nearby flat surface.

8. Slowly loosen the handles until the knife can be freed from the knife bar. Move the knife to

the right or left and remove it from the machine at an angle.

9. Place the knife on the scabbard and remove the knife lifter. Carefully slide the knife to line up

holes in the knife with holes in the scabbard. Secure the knife to the scabbard using the

scabbard screws.

10. Send dull knives to a knife grinder – do not attempt to sharpen your own knives! Knives that

do not have a minimum height of 1-1/2” (3.8 cm) will not function properly and should be

carefully discarded. See the Knife Care Tips Section below for additional information.

7.2 Knife Installation

Knives are always very sharp! Be sure to keep the edge away from your

body and keep other people out of the area while handling the blade. Severe lacerations or

dismemberment could result from careless handling procedures.

1. If a knife is currently installed or the top cover is installed, see the previous section for

instructions on knife removal. The clamp should be lowered to the table. The clamp handle

and top cover should be removed from the machine.

2. Raise the hood. Pull out the cut stick and turn it to a new surface or replace with a new one.

3. Remove the retainer screws from the new blade and screw the knife lifters into the new

blade. Screw the lifters about half way into the knife.

4. Insert the knife assembly into position under the knife bar. Raise the knife into the knife bar

slot as high as it will go. Check all view holes to make sure knife is all the way up. Tighten

the lifters.

NOTE: If the blade will not go in, make sure the lifters are not screwed into the blade too far.

5. Insert and tighten (4) knife bolts into the knife.

6. Loosen the knife lifter handles and remove the knife lifter.

7. Insert and tighten the remaining (2) knife bolts.

8. Reinstall the top cover, clamp handle, and lever-arm handle.

9. Adjust depth of cut by placing sheets of paper across the entire width of the cutting area.

Clamp the paper and make a cut. Adjust the knife depth adjustment screw just until the

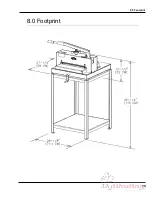

Summary of Contents for Challenge Spartan 150M

Page 20: ...8 0 Footprint 19 8 0 Footprint...