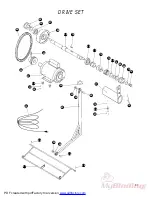

Tool of Perforation:

For larger production is important to always maintain the pins very sharp and clean, avoiding,

like this, barb and overloads of force in the group.

Verifies the tension of the belt periodically, because this should not be nor slack nor excessively

stretched, harming the transmission of force from the motor to the axis.

Belts:

Change of Tool:

To Annul Pins:

Used tools:

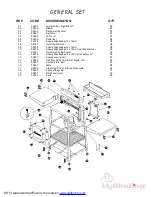

Your MINIMAX, can use several tool types of tools, the change is simple.

DISMOUNT

:

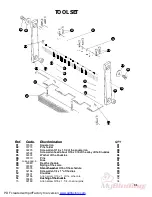

Take out lateral borders (Reference 01 - General Set)

Take out the back cover (Reference 04 - General Set)

Take out the two Knuckles (Reference 17 tool Set)

Take out the three screws of fixation of Pins Set (Reference 14 Tool Set)

Place the new tool in the machine, making the inverse operation to the dismount

MINIMAX can use 3 tool types

For round holes (spiral or double ring);

For squared holes (double ring)

1.Take out the 8 screws (Reference 03 Tool set) of the superior part of the square iron

(Reference 01 Tool Set);

Lean the square iron back and remove the pins wanted (Reference 06 Tool Set);

3) Eeturn the square iron in the original position; and

4) Force upward the pins set (Reference 02 tool set) and to place the 8 screws allen in the original

position.

Screwdriver allen 3/16; and

Screwdriver allen 5/32.

ASSEMBLY

1)

2)

3)

4)

:

•

•

• Rectangular hole.

1)

2)

03

PDF created with pdfFactory trial version