mychefcooking.com

PRODUCT MANUAL COOK PRO - DT.MP.CP.2201.2

10

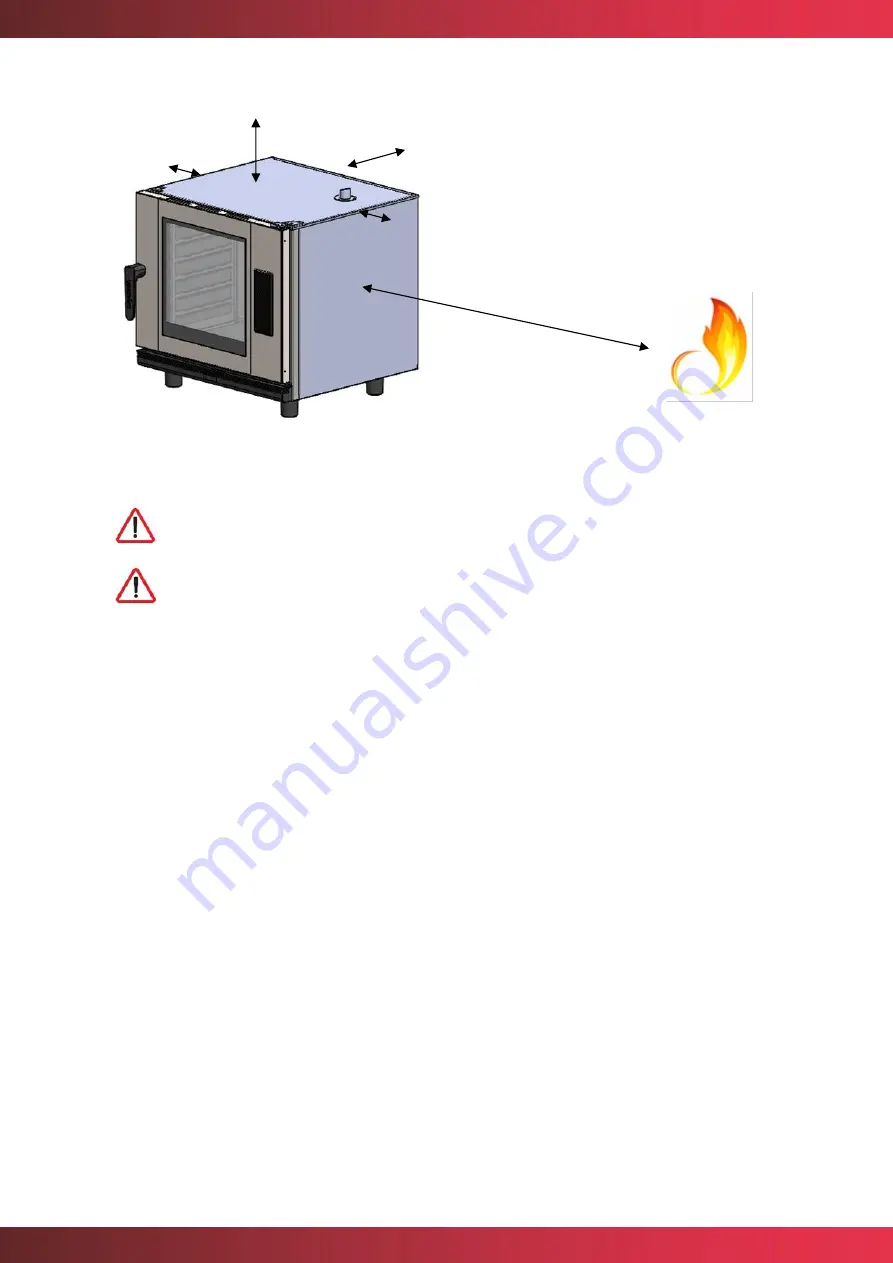

Figure 2. Example of a suitable installation place

Be extremely careful with the cooling zones of the oven. If it draws in fumes

or hot air, this can drastically reduce the life span of the components.

For the installation of stacked Mychef ovens, please follow the instructions

supplied with the stacking kit.

1000mm

50mm

500m

m

50mm

50mm