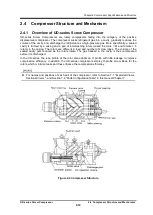

Chapter 2

Compressor Specifications and Structure

UD-series Screw Compressors

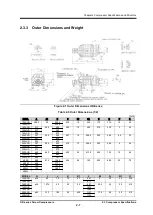

2.2 Model designation of the Compressor

2-2

2.2

Model Designation of the Compressor

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

F

200

L

UD

-

M

E

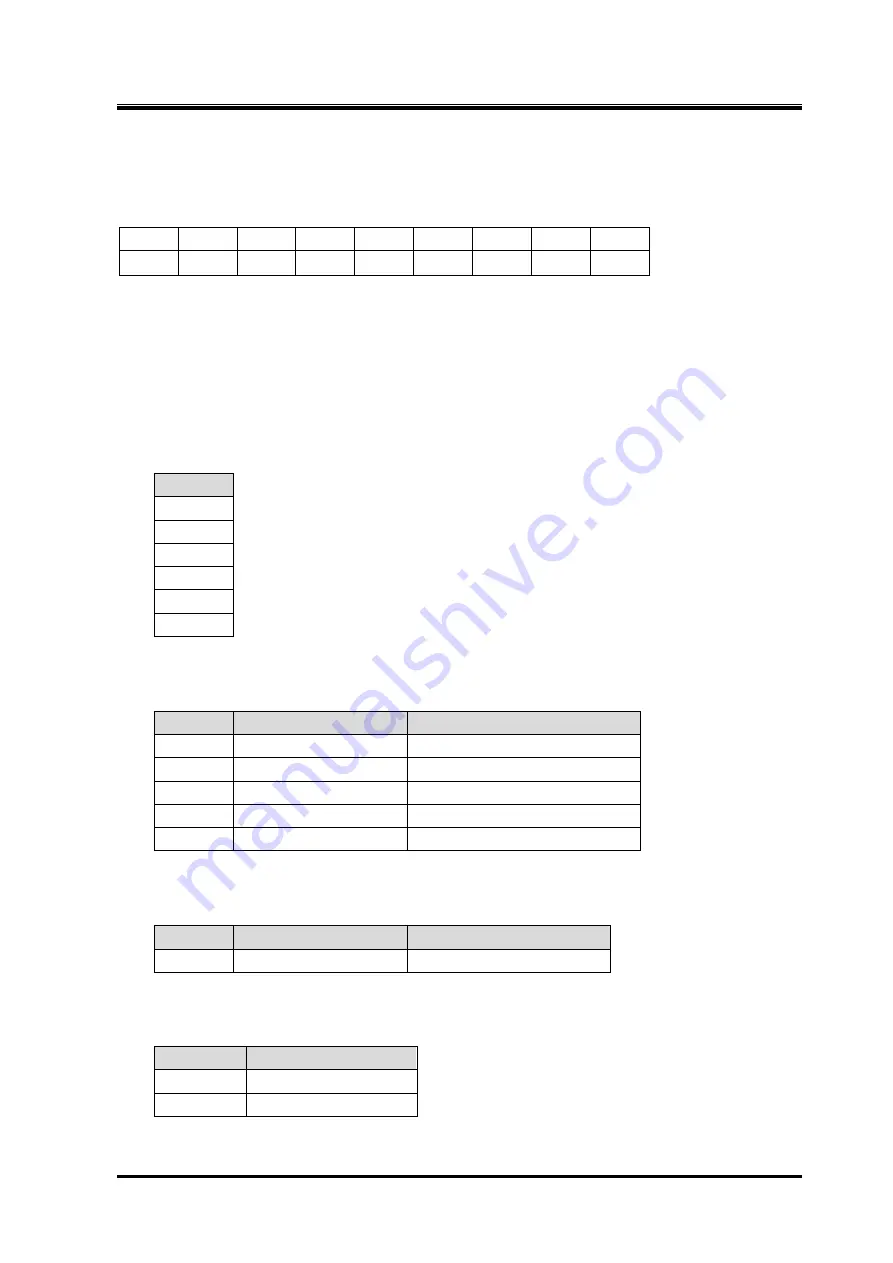

[1] Working fluid

NH

3

, R134a, R404A, R507A

Propane, propylene, CO2

R407C, R407F, R410A

[2] Rotor diameter

Symbol

125

160

200

250

320

400

[3] Rotor length

Symbol

L/D

Remarks

S

1.10

M

1.38

No setting for rotor diameter 125

L

1.65

LL

1.95

Rotor diameter 320, 400

XL

2.20

Rotor diameter 400 only

[4] Discharge direction

Symbol

Discharge direction

Remarks

UD

Sideway

[5] Short cut rotors

Symbol

Specification

No symbol

Standard

S

Short cut rotors

1) Shortcut rates of 5 %, 7 % and 11 % in principle.

2) It cannot be used at H port.