Chapter 5 Maintenance and Inspection

UD-series Screw Compressor

5.5 Reassembly

5-42

List of O-rings used

No.

Install position

125

160

200

250

320

400

9

Suction Cover

P42(2) P42(2)

G55(2)

G60(2)

P58(1)

G95(1)

35

Balance Piston Sleeve

-

G95(1)

P120(1)

P150(1) G190(1) G240(1)

49

Seal Retainer

G85(1) G90(1)

G115(1)

G135(1) G160(1) G160(1)

59

Oil Injection Pipe

P30(2) P30(2)

P40(2)

P46(2)

P32(1)

-

63

Unloader Cylinder

G95(1) G125(1) G150(1)

G190(1) G240(1) G300(1)

65

Unloader Piston

P75(1) P100(1) P125(1)

P155(1) P200(1) P265(1)

73

Unloader Push Rod

P21(1) P21(1)

G30(1)

G35(1)

P44(1)

G45(1)

75

Unloader Cover

G85(1) G110(1) G135(1)

G170(1) G210(1) G270(1)

86

Oil Injection Pipe

G30(1)

-

89

Guide Block

P12(2) P16(2)

P20(2)

P20(2)

P24(2)

-

150

Thrust Bearing Gland Spacer

G220(2) G290(2)

325

"O" ring retainer

P70(2)

432

Main Bearing

G85(4)

G22

☆

(4)

G135(4) G165(4) G200(4)

433

Side Bearing

G85(4)

G22

☆

(4)

G135(4) G165(4) G200(4)

674

Seal Cover

G39

☆

(1)

() indicates the Q'ty.

☆

: JIS W1516 No mark: JIS B2401

5.5

Reassembl

y

Be sure to use only

genuine parts for replacement. Using parts that are

not genuine can cause damage to this product or other devices during operation.

Reassembly of the compressor will be carried out after inspection, repair of parts and confirmation

of parts to be replaced.

Assembly is mostly carried out in the reverse order of disassembly.

Before

starting the assembly work, clean the assembly parts, tools, and workbenches and prepare them

to apply new compressor oil to the assembly parts.

5.5.1

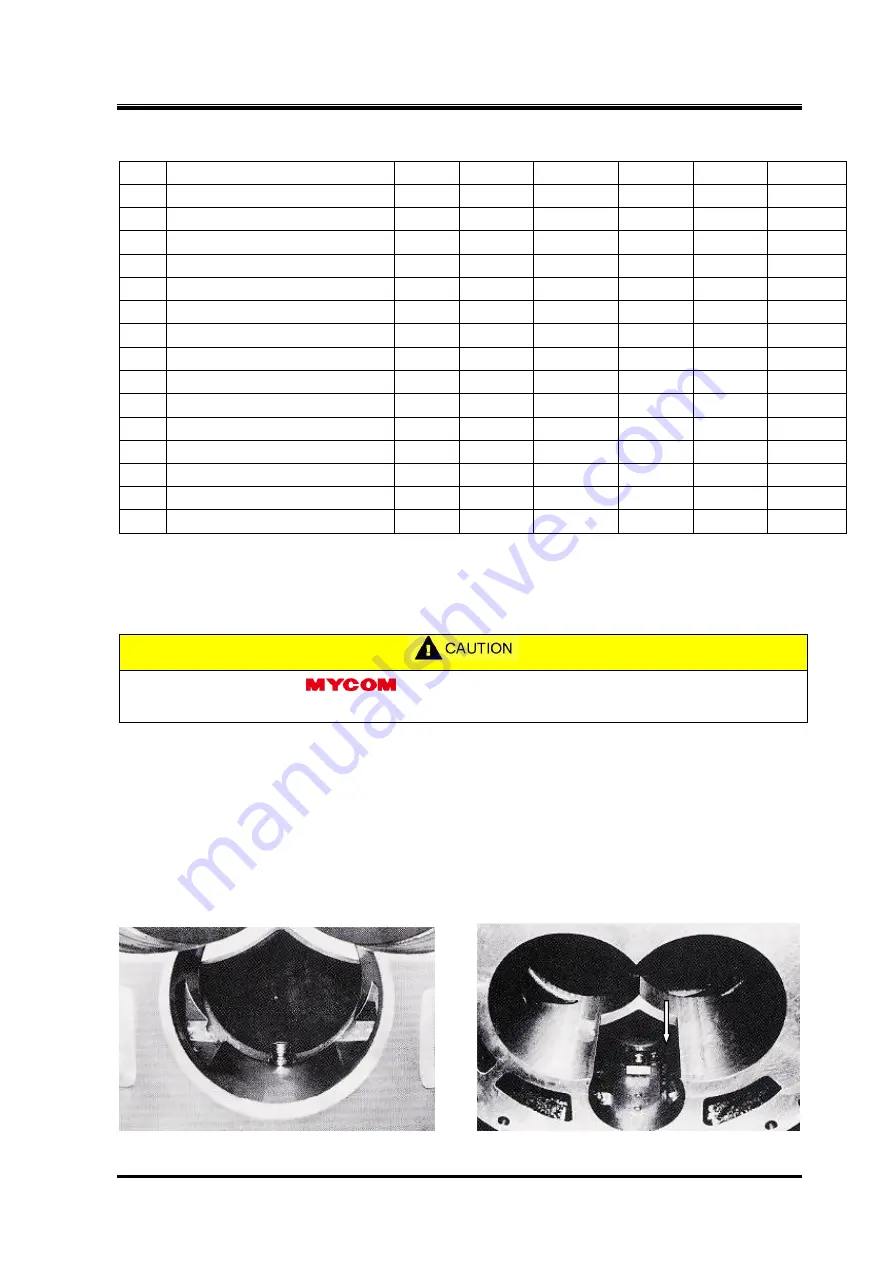

Unloader Slide Valve and Guide Block (125-320)

a)

Install the guide block in the casing and replace and tighten the guide block stem.

Guide block stem inside the casing

Slide Valve and Guide Block