2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor

5.5

Reassembly

1612LSC Speed Increaser Type

5-66

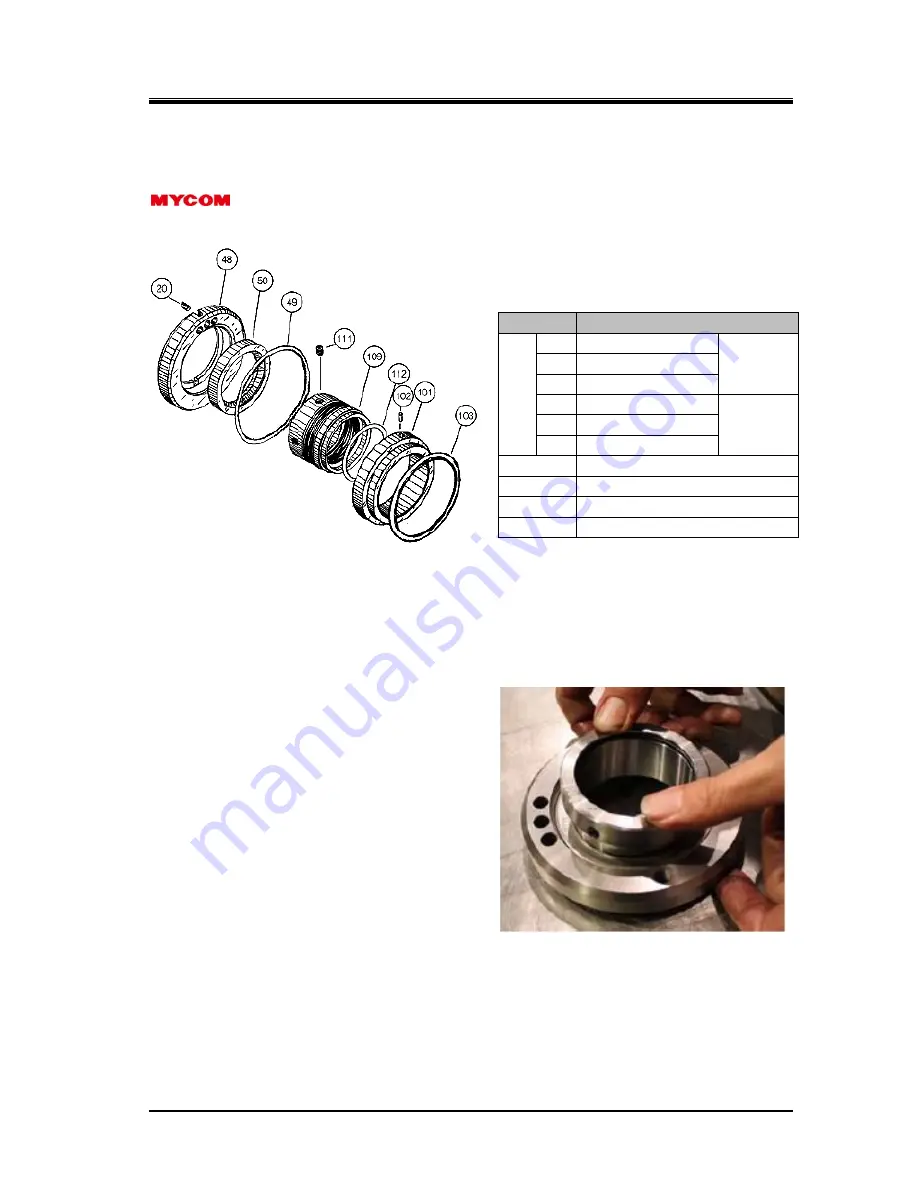

5.5.13

Shaft Seal Block

The BBSE (balance bellows single) type of the mechanical seal assemblies used in current standard

screw compressors as standard specification.

In addition, the BOS (balance O-rings single) type may be used by the specification of the customer.

Figure 5-18 BBSE Type Mechanical Seal Assembly and Related Parts

a) Before assembly, clean the part of the rotor shaft where the seal will be installed.

b) In particular, immediately before assembly, recheck the step part for mounting the shaft seal for

damage.

c) Attach the oil seal [50] to the oil seal retainer

[48].

Since the design modification in November 2002,

the oil seal attachment direction has changed from

the oil seal lip facing the atmosphere side to it

facing the opposite side. This was in order to

improve oil flow from inside the seal box and

ensure that pressure is not excessive. Using a

resinous material such as Teflon as a pad, gently

hit the oil seal while pushing it evenly and fully to

assemble. When it has been pushed in fully, the

sound and feedback will change.

After assembly, check that the seal is aligned with

the retainer and that they are even from the other

side.

d) Install the oil seal retainer with the oil seal attached along the rotor shaft using two M8 eyebolts. At

this time, ensure that the retainer’s oil hole is on the upper side of the rotor shaft, and accurately

align the spring pin [20] for stopping rotation on the speed increaser gear casing cover with the

retainer notch part.

After assembly, rotate the retainer’s eyebolts to

check that they are secure. If they are secure, the retainer will not rotate.

P/N

Part Name

100

101

Mating ring

Stationary

ring

102

Insert lock pin

103

O-ring

109

Seal collar

Rotating

ring

111

Seal collar set screw

112

O-ring

20 Spring

pin

48

Oil seal retainer

49 O-ring

50 Oil

seal