2202L5JE-DA-C5-N_2015.05.

2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor

2.6 Gas and Oil Flow

1612LSC Speed Increaser Type

2-10

2.6

Gas and Oil Flow

The screw compressor’s compression process is

described earlier in this manual.

Gas for the compound speed increaser type 1612LSC

compressor passes from the evaporator and through

the suction strainer and check valve, and is sucked

into the center part of the compressor

①

, and it is

compressed at the low-stage

②

.Then the

compressed gas is discharged at

③

.

③

and

④

are

connected by piping through which gas used for super

cooling is mixed in from the liquid cooler.

Lubricating oil injected at the low-stage is, while kept

mixed with gas, suctioned from

④

into the high-stage.

After being compressed at

⑤

, the gas mixed with

lubricating oil is discharged from

⑥

to the oil separator, and then sent to the condenser.

The oil is cooled even without intermediate gas cooling, so the high-stage discharge temperature can

be maintained at below 90 °C.

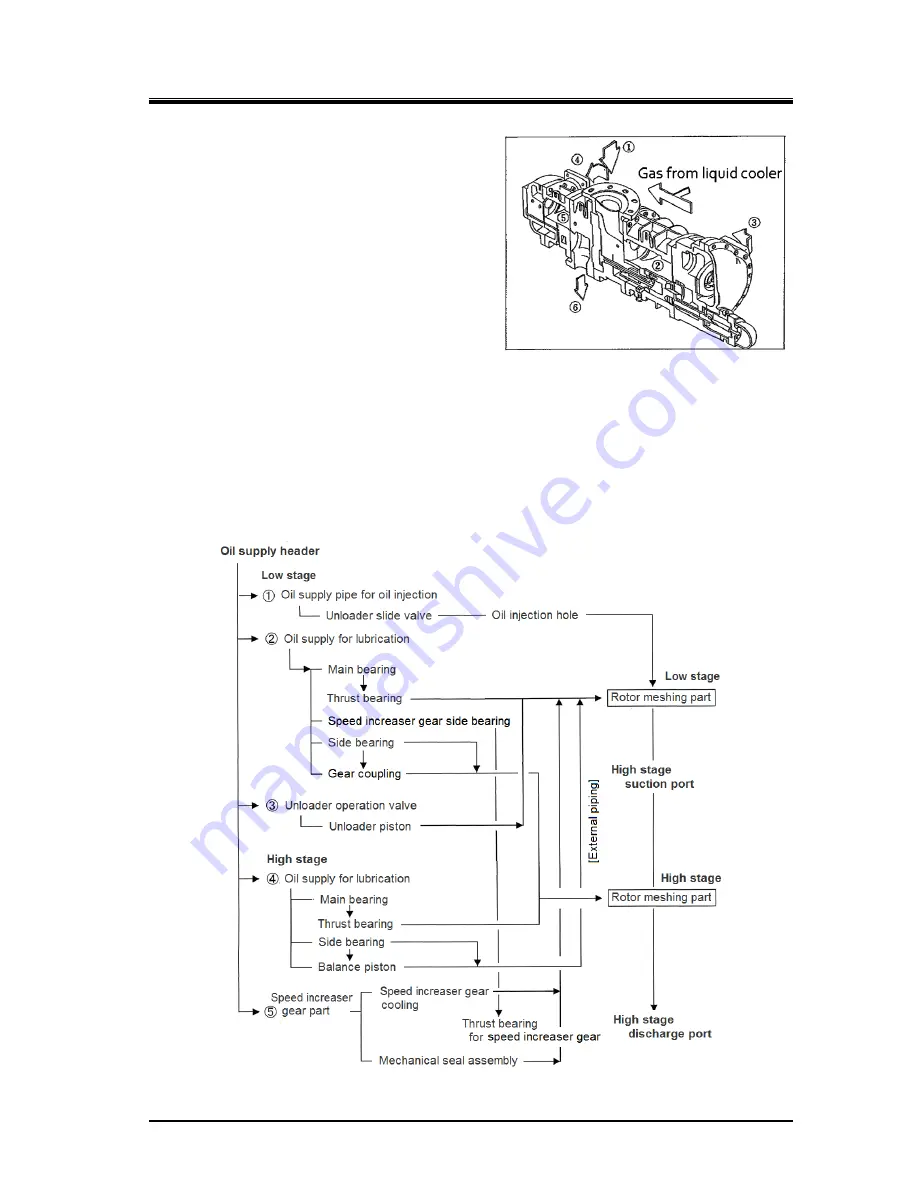

Oil Supply Route

Lubricating oil is split into 4 flows as shown in Figure 2-12, and after providing lubrication, it is

mixed with discharge gas and leaves the compressor. In standard configurations, oil injection is not

performed at the high-stage.

Figure 2-12

1612LSC Speed Increaser Type Oil Supply Route

Figure 2-11 Gas Flow