2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor

5.3 Compressor Disassembly Preparation

1612LSC Speed Increaser Type

5-12

5.3.5 Compressor Removing and Lifting

The work to lift up or move the compressor must be performed by a qualified operator.

Make sure that the lifting equipment and wires have sufficient load capacity for the

compressor before starting the compressor lifting work.

Never try to perform disassembly or assembly while the compressor is lifted in the air.

Since the suction piping is located immediately above the compressor, hold it up or partially

remove it before lifting the compressor.

For the lifting positions of the compressor, refer to Figure 3-1 in page 3-3 of Chapter 3 in this

manual.

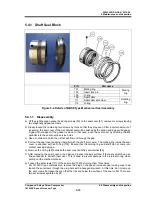

If the planned overhaul work includes separation between low-stage and high-stage blocks of the

compressor, place the compressor on a special stand as shown in Photo 004 and then remove

eight or more hexagon head cap screws around the bottom flange part.

Never try to remove

these bolts while the compressor is lifted in the air.

Note that these bolts cannot be removed

once the compressor is placed on the work bench.

Lifting the Compressor

Lower Bolts for Tightening Rotor Casing

5.3.6 Removing Oil from Inside the Compressor

Since there is a large quantity of oil inside the compressor, remove it beforehand.

There is a plug [10] under the suction cover [5-1] and a plug [15] under the bearing head [11-1].

Most of the oil will flow from these plug holes. The remaining oil will flow onto the work bench during

disassembly.

Main locations remaining oil are a) inside the unloader cylinder, b) inside the balance piston cover, c)

inside the seal cover [51], and d) inside the suction cover [5-1]. Prepare a tray and cloth for oil that spills

during disassembly.