2200LZJE-HO-C6-N_2013.12.

Chapter 5 Maintenance

Compound 2-stage Screw Compressor 2016**C

5.7 Reassembly

5-59

5.7.12 Mechanical Seal

The standard mechanical seal assemblies used in the current

standard screw

compressors are of the BBSE (balance bellows single) type.

In addition, the BOS (balance O-ring single) type may be used depending on the specifications of the

customer.

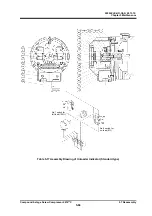

Figure 5-14 BBSE Type Mechanical Seal Assembly

a) Before assembly, clean the portion where the rotor shaft seal will be installed.

b) In particular, recheck immediately before assembly that the stepped portion where the axial seal will

be mounted is free of damage.

c) Attach oil seal

【

50

】

to oil seal retainer

【

48

】

.

Since the design change notification issued in November 2002, the oil seal attachment direction has

been changed from "facing the atmosphere side" to "facing the opposite side". The purpose of this

change is to improve oil flow from inside the seal box so that the pressure will not rise too high.

However, in rare cases, assembling the oil seal retainer becomes difficult in the following work.

Then, the previous attaching direction is allowed to be used.

Place a Teflon or other kind of resin block on the oil and tap on the block to push the oil seal into the

retainer evenly until it bottoms. When it gets fully pushed in, you will know by the change in the

tapping sound and feel.

After assembly, check that the step formed at the boundary between the oil seal and the retainer is

even. See from the opposite side, and confirm that they are evenly assembled.

d) Insert the O-ring

【

744

】

in the inner periphery of the oil seal

sleeve

【

528

】

, which should then be attached to the oil seal

retainer with oil seal inserted (Photo 116).

Photo 116