2200LZJE-HO-C6-N_2013.12.

Chapter 5 Maintenance

Compound 2-stage Screw Compressor 2016**C

5.7 Reassembly

5-61

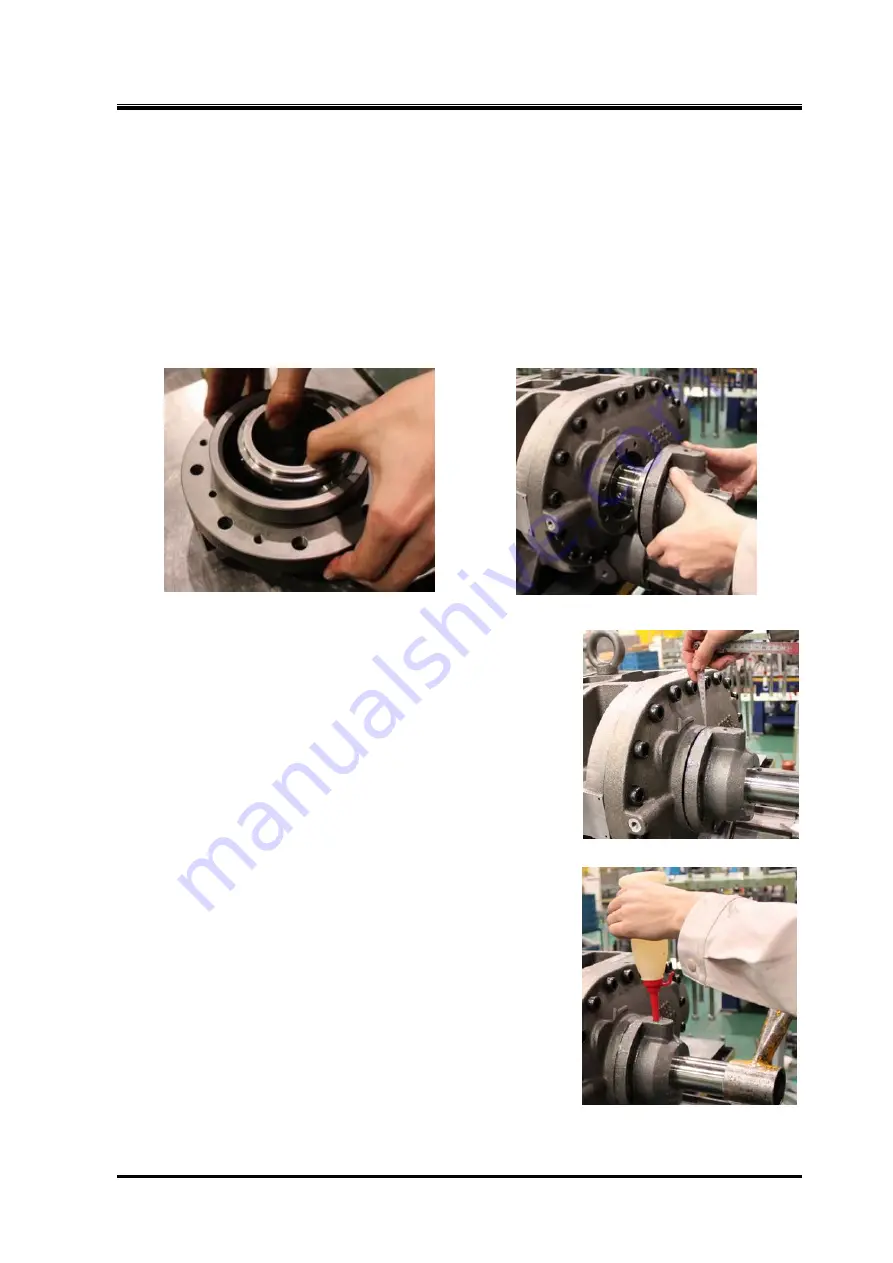

j) Attach the O-ring

【

103

】

for mating ring and mating ring

【

101

】

to seal cover

【

51

】

(Photo 122).

k) Apply oil to the seal cover gasket

【

52

】

, align the gasket oil hole with the oil hole on the seal cover

flange surface, and affix the gasket.

* With the standard internal oil supply type compressors, the bearing cover and the seal cover are

connected by an oil supply hole. Oil flows from the notch in the seal cover through the groove to the

upper side of the seal cover, and then flows through the drilled oil supply hole to the upper sliding

surface of the mechanical seal.

m) Install the seal cover with the gasket, so that the oil removal piping of the seal cover is on the bottom

side.

At this time, assemble it carefully, either at a right angle or by delaying the upper side slightly, while

paying attention not to cause the mating ring inside the seal cover hit against the rotor shaft.

Photo 122 Photo 123

n) The seal ring and the mating ring sliding surface will come into

contact midway through attachment. At this moment, check the

dimensions between the seal cover gasket and the bearing

cover flange surface by using a taper gauge (Photo 124). This

value is called tightening allowance for seal. It is used when

checking the sliding face pressure between the rotating ring and

stationary ring of the seal.

In case of BBSE-type seal of the 2016**C, if this value is not

within the range between 2 and 3 mm, measures should be

taken, such as replacement of mechanical seal assembly or

addition of another gasket.

With the 2016**C compressor, the thickness of the seal cover

gasket is 0.5 mm.

o) When the seal tightening allowance is proper, push the seal

cover firmly into the bearing cover. Since there is repulsion force

of the seal bellows, keep it pushed firmly and tighten the two

hexagon socket head cap screws

【

53

】

(for tightening the seal

cover) evenly at positions 180 degrees apart. When there is no

gap between the flange surface and the gasket, tighten all of the

remaining bolts to the specified torque (50 N·m).

p) When tightening of the seal cover is finished, supply oil to the

seal cover while rotating the rotor shaft (Photo 125).

Photo 124

Photo 125