2200LZJE-HO-C6-N_2013.12.

Chapter 2 Configuration and Specifications of Compressor

Compound 2-stage Screw Compressor 2016**C

2.1 Features of the Compound 2-stage Screw Compressor 2016**C

2-1

Chapter 2 Configuration and Specifications of

Compressor

2.1

Features of the

Compound 2-stage Screw

Compressor 2016**C

The 2-stage compression system, which has hitherto required two units of standard-type screw

compressor for its embodiment, can now be realized by a single unit of compound 2-stage screw

compressor.

Generally, screw compressors use oil injection to keep discharge temperature at a low level during

operation without loss of volumetric efficiency even at high compression ratios. It can, therefore, be

operated with a single-stage compression system even at evaporative temperatures near -40

°

C.

However, for normal use at low temperatures, a 2-stage compression system is applied in order to

improve KW/RT (ratio of power consumption versus cooling ability). If the 2-stage compression system

is configured with standard-type screw compressors, at least two screw compressor units need to be

installed, one on the high-stage and the other on the low-stage, which inevitably requires double

installation of the entire system including machinery, motors, utilities, etc.

This 2-stage screw compressor is produced to solve this problem. It is a single unit that has two

single-stage compressor units combined into one.

The 2016**C model has a capacity control mechanism for startup load reduction on the high-stage, and

a capacity control mechanism for coping with load change on the low-stage.

There are various combinations of machine control methods/capacity control methods. However, as

they are not directly related to the inspection of the compressor, they are omitted here.

2.2

Model Designation of the Compressor

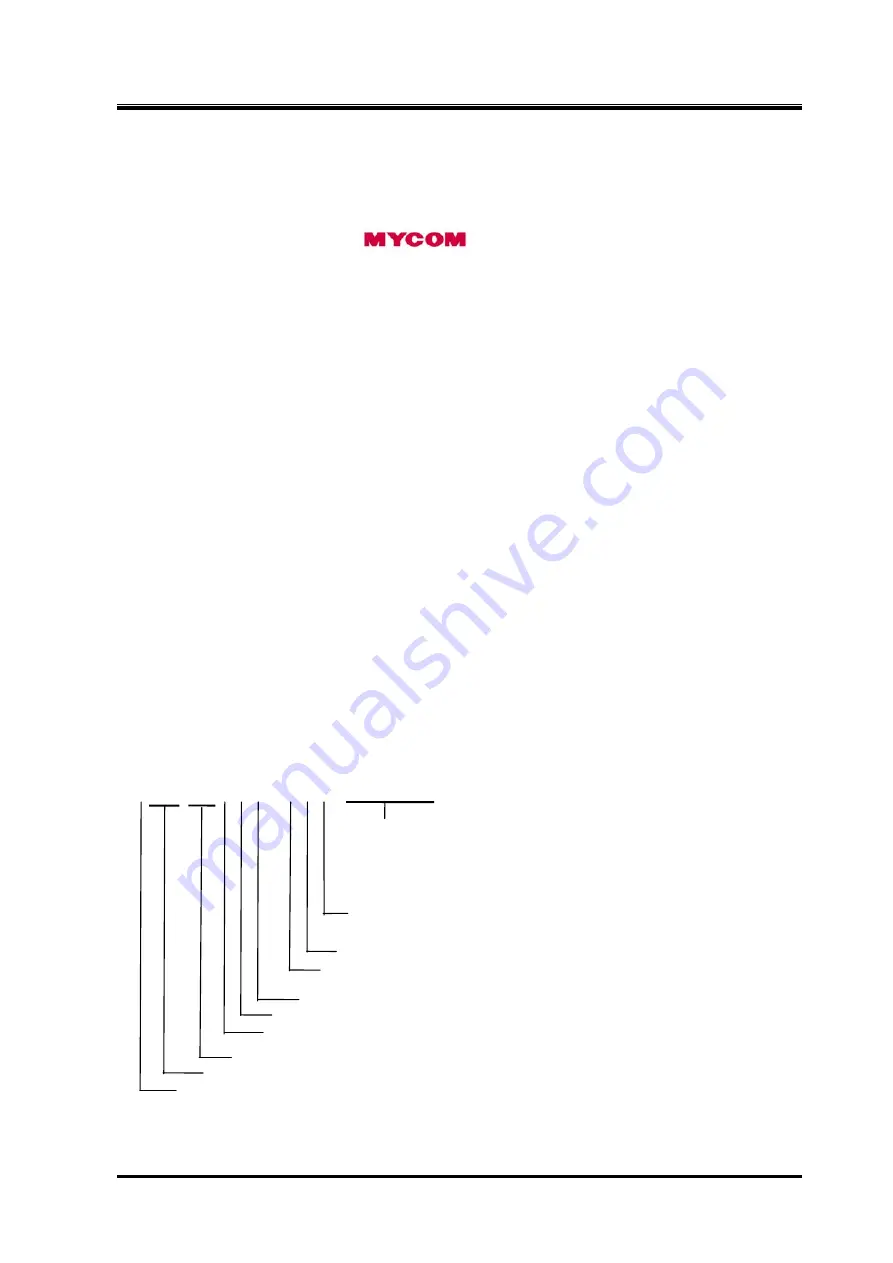

This manual describes 2016**C-*B*-51 and 2016**C-*B*-61 models.

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

*2016**C-*B*-51/61

5: Power frequency (6: 60Hz)

1: Indicates that it is a motor directly connected type.

* Unless specifically specified, machines manufactured in

September, 2010 or after do not have this indication engraved

on their nameplate.

Vi (volume ratio) specified for the high-stage discharge port,

standard value of which is

L

or

M

Means a booster (low-stage machine)

Vi (volume ratio) specified for the low-stage discharge port, standard

value of which is

L

or

M

Stands for Compound (compound 2-stage machine)

Specifications of high-stage rotor length, which is

L

,

M

or

S

Specifications of low-stage rotor length, which is

L

,

M

or

S

High-stage rotor diameter of 160

Low-stage rotor diameter of 200

Indicates working fluid

(Example: N = Ammonia, F= Freon, P = Propane, HE = Helium)