2200LZJE-HO-C6-N_2013.12.

Chapter 2 Configuration and Specifications of Compressor

Compound 2-stage Screw Compressor 2016**C

2.5

Mechanisms

2-11

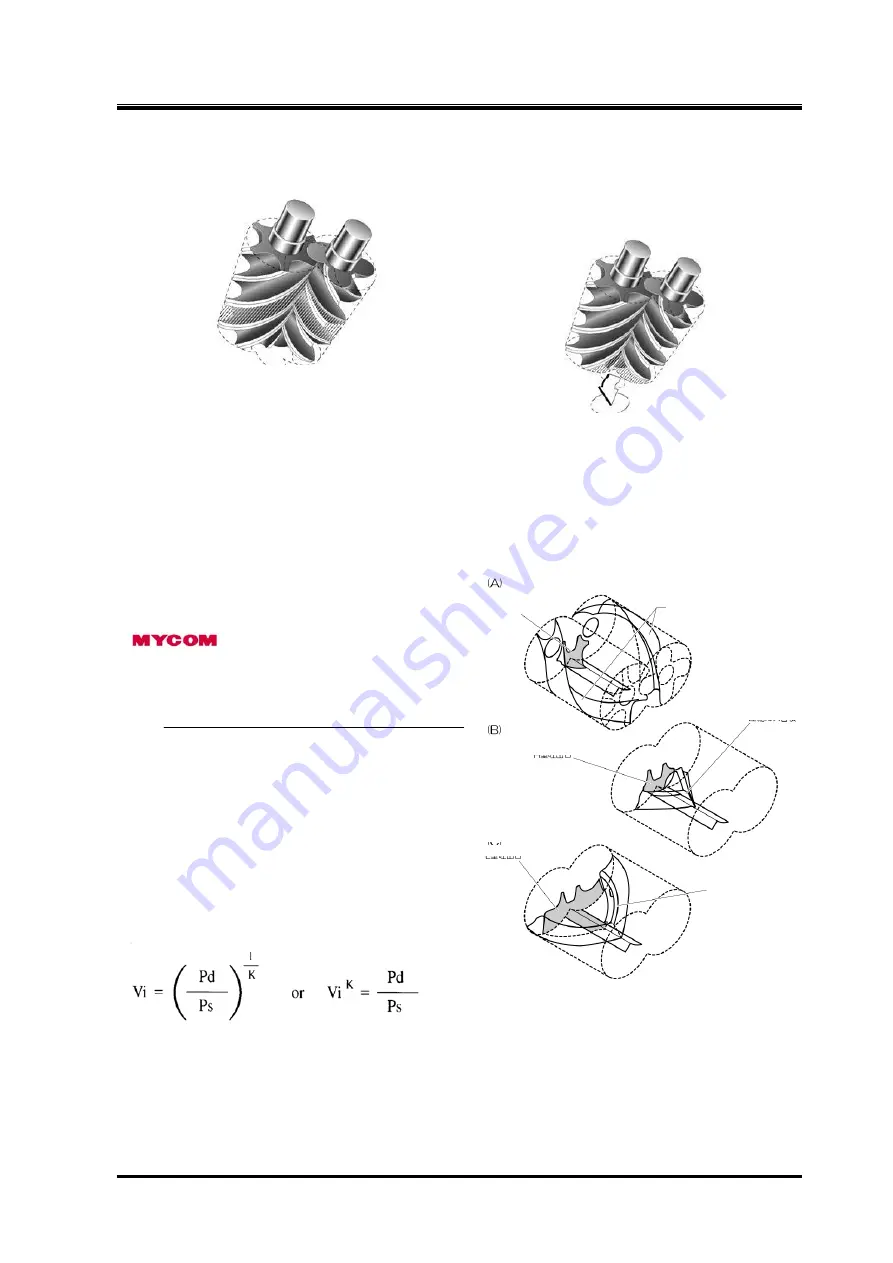

2.5.3 Compression

Process

As the rotors rotate further, the volume between the rotor teeth and grooves decreases while the

sealing line moves toward the discharge side, which compresses the trapped refrigerant gas.

2.5.4 Discharge

Process

The volume between the rotor teeth and grooves decreases to a level predetermined by the discharge

port. With the rotations of the rotors, the compressed refrigerant gas is pushed out to the discharge

port.

2.5.5 About Volume Ratio (Vi)

Volume ratios (Vi) are indicated in property tables or

catalogs by using port symbols L, M and H.

The volume ratio represented by each symbol

(

screw compressor) is as follows:

L=2.63, M=3.65, H=5.80.

Volume of suctioned refrigerant gas

immediately before the start of compression

Vi =

Volume of refrigerant gas just before

pushed out to discharge port

Which volume ratio (L, M or H ) should be used is

decided according to operating conditions. If the

compressor is used with a volume ratio that does not

match operating conditions, operation will go

inefficiently wasting the power.

The relationship between volume ratios and generally

used compression ratios is as follows:

Figure 2-11 Volume Ratio

(Vi)

K

=

π

i

= Pd/Ps K = Cp/Cv of refrigerant gas

Vi = Design volume ratio

π

i = Design compression ratio

As Vi is affected by the constant of the refrigerant gas, its value that corresponds to the compression

ratio will change depending on the refrigerant gas.

Figure 2-9 Compression Process

Figure 2-10 Discharge Process

Discharge port

Volume of suction gas

H-type discharge port

Volume of compressed gas

Volume of

compressed gas

L-type discharge

port

(C)