2201Q4JE-MY-C9-N_2018.01.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 4032**C

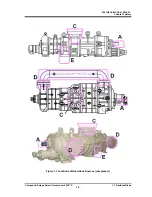

2.1 Overview of MYCOM 4032**C

2-1

Chapter 2 Compressor Specifications and Structure

2.1

Overview of

4032**C

The 2-stage compression system, which has hitherto required two units of standard-type screw

compressor for its embodiment, can now be realized by a single unit of compound 2-stage screw

compressor.

Generally, screw compressors use oil injection to keep discharge temperature at a low level during

operation without loss of volumetric efficiency even at high compression ratios. It can, therefore, be

operated with a single-stage compression system even at evaporative temperatures near -40

°

C.

However, for normal use at low temperatures, a 2-stage compression system is applied in order to

improve kW/RT (ratio of power consumption versus refrigerating capacity). If the 2-stage compression

system is configured with standard-type screw compressors, at least two screw compressor units need

to be installed, one on the high-stage and the other on the low-stage, which inevitably requires double

installation of the entire system including machinery, motors, utilities, etc.

This 2-stage screw compressor is produced to solve this problem. It is a single unit that has two

single-stage compressor units combined into one.

The 4032**C model is currently the biggest size compressor in the compound 2-stage

compressor C-series. In addition to general refrigeration systems and air conditioning systems, the

4032**C model has been used in variety process gas compression systems due to the ability to meet

various requirements specifications, i.e., temperature conditions, pressure conditions, power conditions,

etc. As a result, most of the products which have been manufactured and shipped until now, are special

specification products.

If there are different points of specifications between your purchased compressor and the standard

specification compressor described in this manual, refer to the document showing specifications of your

purchased compressor.

2.2

Model Designation of the Compressor

This manual describes 4032**C-*B*-51 and 4032**C-*B*-61 models.

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

*

4032

**

C

-

*

B

*

-

51/61

5: Power frequency (6: 60Hz)

1: Indicates that it is a motor directly connected type.

* Unless specifically specified, machines manufactured in

September, 2010 or after do not have this indication engraved

on their nameplate.

Vi (volume ratio) specified for the high-stage discharge port,

standard value of which is

L

or

M

Means a booster (low-stage machine)

Vi (volume ratio) specified for the low-stage discharge port, standard

value of which is

L

or

M

Stands for Compound (compound 2-stage machine)

Specifications of high-stage rotor length, which is

LL

,

L

,

M

or

S

Specifications of low-stage rotor length, which is

XL

,

LL

,

L,

M

or

S

High-stage rotor diameter of 320

Low-stage rotor diameter of 400

Indicates working fluid (Example: N = Ammonia, F= Fluorocarbon, P = Propane, HE = Helium)

There are cases that the symbol indicating the special specification is engraved other than these.

In such a case, refer to the specifications of each compressor.