2201Q4JE-MY-C9-N_2018.01.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 4032**C

2.3

Compressor Specifications

2-2

2.3

Compressor Specifications

2.3.1 Specifications

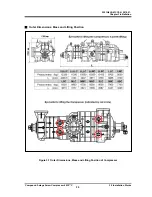

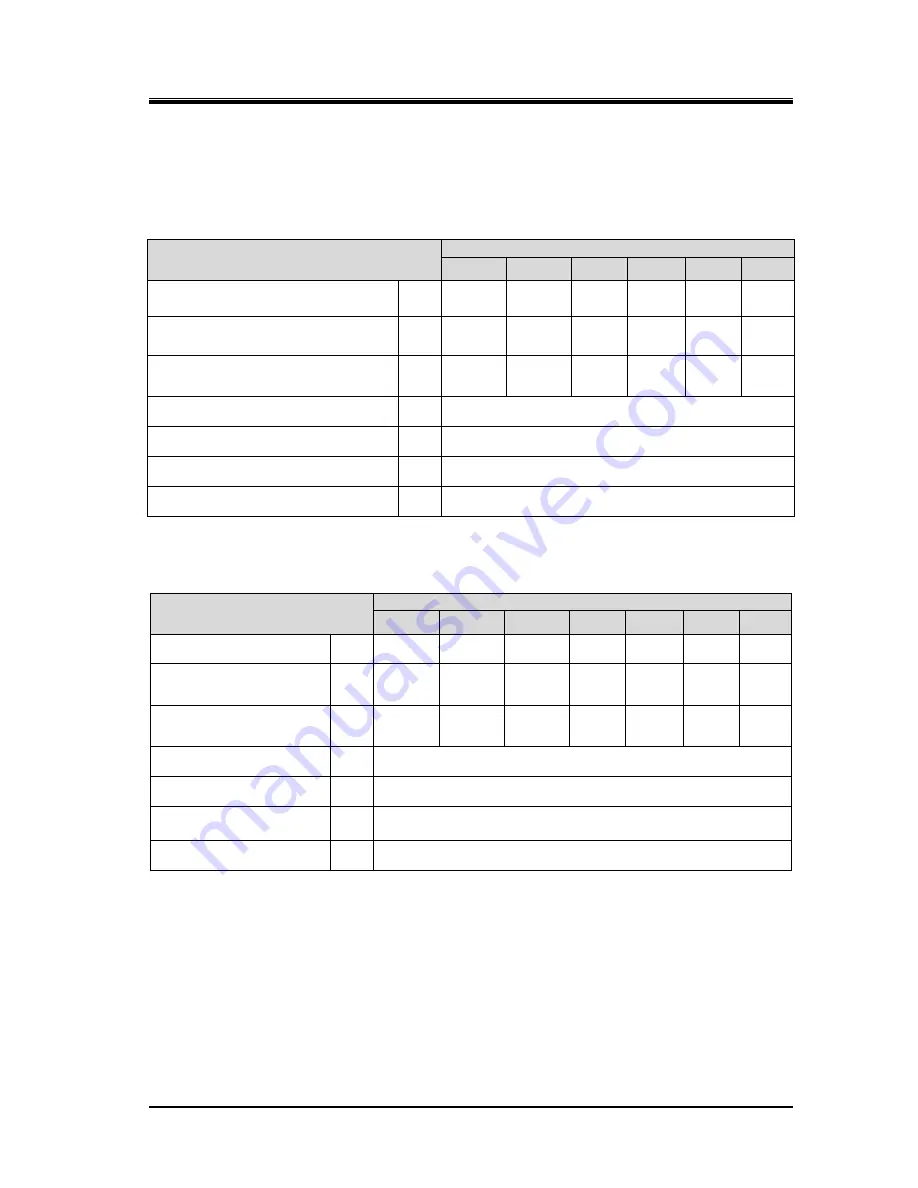

Table 2-1 4032**C Screw Compressor Specifications (1/2)

Items

Model

X L L L C L L L L C L L L C L L M C L L S C

L L C

Product mass

kg

12320

*Note1

11250

10500

10350

10150

9700

Low-stage swept volume

@3550 min

-1

/2950 min

-1

m

3

/h

15600

/12900

13800

/11500

13800

/11500

13800

/11500

13800

/11500

11700

/9700

High-stage swept volume

@3550 min

-1

/2950 min

-1

m

3

/h

6740

/5600

6740

/5600

5700

/4740

4760

/3960

3820

/3170

5700

/4740

Working fluid

-

Ammonia, Hydrofluorocarbon, Hydrocarbons, Other.

Design pressure

MPa

2.6

Capacity control (Actual load)

%

10 to 100

Rotation direction

-

Counterclockwise viewed from motor

*Note1: Product mass of 4032XLLLC is a data of the specifications for cast steel casings.

Table 2-2 4032**C Screw Compressor Specifications (2/2)

Items

Model

L S C

M L C

M M C

M S C

S L C

S M C

S S C

Product mass

kg

9350

8900

8750

8550

8050

7900

7700

Low-stage swept volume

@3550 min

-1

/2950 min

-1

m

3

/h

11700

/9700

9800

/8140

9800

/8140

9800

/8140

7800

/6480

7800

/6480

7800

/6480

High-stage swept volume

@3550 min

-1

/2950 min

-1

m

3

/h

3820

/3170

5700

/4740

4760

/3960

3820

/3170

5700

/4740

4760

/3960

3820

/3170

Working fluid

-

Ammonia, Hydrofluorocarbon, Hydrocarbons, Other.

Design pressure

MPa

2.6

Capacity control

(Actual load)

%

10 to 100

Rotation direction

-

Counterclockwise viewed from motor

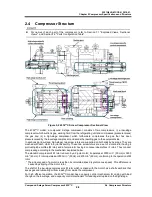

Unless otherwise noted, the pressure unit MPa represents the gauge pressure in this manual.

For limits of working temperature and pressure, refer to Section2.3.2 "Operation Limits" in this

Chapter.

For sizes of connecting piping, refer to Section 2.3.2 "Outer Dimensions" or Section 3..2.4 Table

3-1 " List of Connecting Pipes (Compressor)" in this manual.