2201Q4JE-MY-C9-N_2018.01.

Chapter 3 Installation

Compound 2-stage Screw Compressor 4032**C

3.2 Installation Works

3-4

3.2.4 Preparation for Installation

Installation Space

Secure sufficient working space for easy operation, cleaning, maintenance, and inspection.

Illumination

Prepare illumination devices which allow easy operation, cleaning, maintenance, and inspection.

Ventilation

If natural ventilation is insufficient, install ventilation fans according to the relevant regulations.

Piping

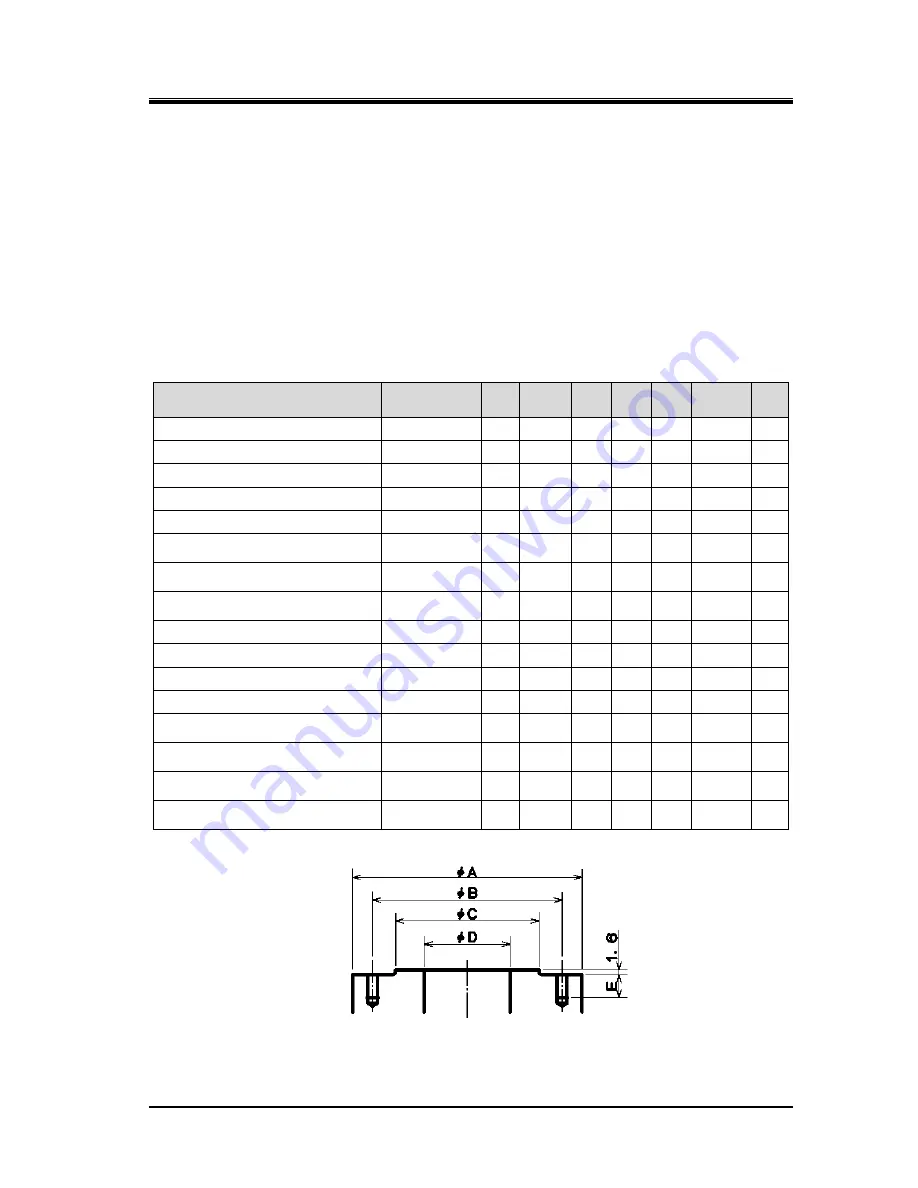

Table 3-1 List of Connecting Pipes (Compressor)

I t e m

S i z e

Φ

A

Φ

B

Φ

C

Φ

D

E

UNC Bolt

Size

Qty

(Bolt)

Suction gas inlet

ANSI #300 16”

650

571.5

470

400

65

1-1/4-7

20

High-stage gas inlet

ANSI #300 12”

521

451

381

300

60

1-1/8-7

16

Low-stage gas outlet

ANSI #300 12”

521

451

381

320

60

1-1/8-7

16

High-stage discharge gas outlet

ANSI #300 8”

381

330

270

200

50

7/8-9

12

Lubricating oil inlet for low-stage TPTB

ANSI #300 2”

165

127

92

50

35

5/8-11

8

Lubricating oil inlet for low-stage main

bearing

ANSI #300 2”

170

127

92

40

35

5/8-11

8

Lubricating oil inlet for low-stage side

bearing

ANSI #300 1”

156

89

51

30

35

5/8-11

4

Oil inlet for oil injection

ANSI #300

2-

1/2”

190

149

105

65

40

3/4-10

8

Lubricating oil inlet for high-stage bearing

ANSI #

300 2”

165

127

92

45

35

5/8-11

8

Oil outlet of low-stage suction cover

ANSI #300 1/2”

95

66.5

35

18

25

1/2-13

4

Oil outlet of low-stage bearing head

ANSI #300 1”

124

89

51

23.5

35

5/8-11

4

Oil outlet of high-stage suction cover

ANSI #300 1/2”

95

66.5

35

18

30

1/2-13

4

Lubricating oil inlet for low-stage capacity

control (load)

NPT 3/4

-

-

-

-

-

-

-

Lubricating oil inlet for low-stage capacity

control (unload)

NPT 3/4

-

-

-

-

-

-

-

Lubricating oil inlet for high-stage capacity

control (load)

NPT 1/2

-

-

-

-

-

-

-

Lubricating oil inlet for high-stage capacity

control (unload)

NPT 3/8

-

-

-

-

-

-

-

Figure 3-2 Dimensions of the Joint (Compressor)

for the ANSI #300 Flange