2201Q4JE-MY-C9-N_2018.01.

Chapter 3 Installation

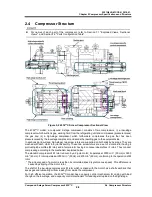

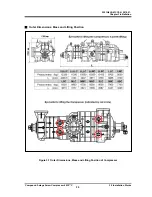

Compound 2-stage Screw Compressor 4032**C

3.2 Installation Works

3-6

3.2.5.3 Piping Connection

Refrigerant Piping

Observe the following when connecting the refrigerant piping to the compressor.

The compressor is one of the few devices installed within the package unit that have moving

components. These moving components are adversely affected by foreign substances within

the system (scale, dust, spatter, etc.). Therefore, when connecting the piping, do not allow any

of such foreign substances to enter inside.

Some compressors (mainly those for export) are charged with nitrogen gas to prevent rust. Be

sure to release the pressure before starting piping work.

Be sure not to allow moisture to enter the piping. There is a high probability that it will cause

trouble after the start of operation. Be sure to assemble piping when it is dry.

Cover flanges are attached to the compressor's low-stage gas outlet and high-stage gas inlet.

After installation, be sure to attach piping (intermediate piping) that links the both connection

ports.

Improper piping may cause operating problems such as oil not returning to the compressor or

liquid flow-backs.

When connecting the piping to the compressor, use piping that is the same size as the

compressor connection port. If the pipe size of the piping is smaller than the compressor

connection port, the flow of lubricating oil or refrigerant will be obstructed leading to problems.

Do not let the mass of the piping connected to the compressor applied onto flanges or joints.

Be sure to prepare proper supports for piping.

3.2.5.4 Equipment and Devices for Protection of the Compressor

Oil Filter

According to the requirements of the use of the package unit or the standard to apply, install an oil

filter of appropriate filtration precision in the lubrication system of the compressor.

In case of general applications such as closed-cycle refrigeration systems, we recommend to use

an oil filter with beta ratio in the range of

β

20

≥ 150 that conforms to requirements of NAS 1638

class 8 or ISO 4406 17/15/13.

When the package unit requires API 619 4th/5th edition conformity, use an oil filter with beta ratio in

the range of β

10

≥200.

The oil filter may be clogged just after test operation. We recommend installing two oil filters in

parallel. This will enable replacement of either filter during operation.

Oil Heater for Oil Separator

To preserve the temperature of the lubricating oil before starting the compressor, install an oil

heater on the oil separator. Make sure to install a protection function (thermostat, etc.) to prevent

overheating.

Suction Strainer

When compatible (inter-soluble) oil is used, the mesh size of suction strainer should be not less

than 200 meshes. When incompatible (non- inter-soluble) oil is used, it should be not less than 100

meshes.

For details about compatible and incompatible oils, refer to Section 4.1 "Lubricating Oil (Refrigerant

Oil)" in this manual Chapter 4.

During the commissioning, small particles and scale may come from the system. We recommend

installing a finer filter temporarily.