2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

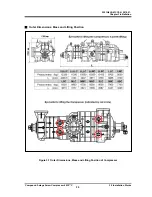

Compound 2-stage Screw Compressor 4032**C

5.1 Precautions for Maintenance and Inspection

5-2

When checking the operation data of units and executing other daily maintenance

services, pay particular attention to avoid touching the area heated to a high

temperature causing skin burns or inadvertently moving the handle of a valve

leading to an erroneous operation.

In the disassembly/inspection workplace, secure a sufficient space for temporary

storage of the removed parts and tools, replacement parts, and for the

disassembling work as well as safety passages, and then put up necessary off-limit

signs.

In the workplace, secure a sufficient space and refrain from putting tools directly on

the floor or from haphazardly laying wires.

Keep the floor clean all the time. Leaving the floor smeared with oil and the like

causes it to be slippery and may result in the fall and injury of personnel. Thus, do

not leave it but wipe it off right away.

Make sure that the temperature of the high temperature sections such as

bearinghead and discharge lines has been cooled down to normal ambient

temperature, before working on them.

When disassembling and reassembling the compressor, use the specified tools

properly. Before starting to use those tools, gain the full understanding of their

characteristics and the method for use.

During the maintenance service, keep the tools clean all the time. Using those tools

smeared with oil increases the risk of slip and fall, leading to an injury. Also during

the service, there is a risk of foreign matters intruding inside the compressor to

cause its damage.

Parts are slippery with oil. Fully watch out for the risk of any object falling down.

Pay attention to any parts falling down, which could lead to personal injury.

Before disassembly, inspections, and handling of the compressor, sufficiently

understand the disassembly and assembly procedures.

This manual is not intended to provide complete disassembly and assembly

procedures for the compressor. Instead, it describes only the important points in

relation to the maintenance service of the compressor.

If complete disassembly and assembly of the compressor are required, please

contact your nearest sales office or service center of MAYEKAWA.

When removing a part, be careful not to damage it.

Place the removed parts on a clean workbench in an orderly manner.

For cleaning parts, use kerosene and/or machine parts cleaner.

Washed parts shall be dried by compressed air or wiped up using clean cloth. Do

not use synthetic textiles or woolen textiles to prevent fibers from attaching the

parts.

When separating the assembled compressor casings, sometimes it is difficult to

separate them due to the gasket stuck. In such a case, never hammer in a screw

driver or flat chisel into the gap. Screw jack bolts using the screw holes to separate

the casing each other. When some gap is observed between them, use a scraper

to remove one side of the gasket from the surface.

Removed bolts from each part should be classified into each used section to

prevent confusion.