2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 4032**C

5.4 Disassembly and Inspection

5-18

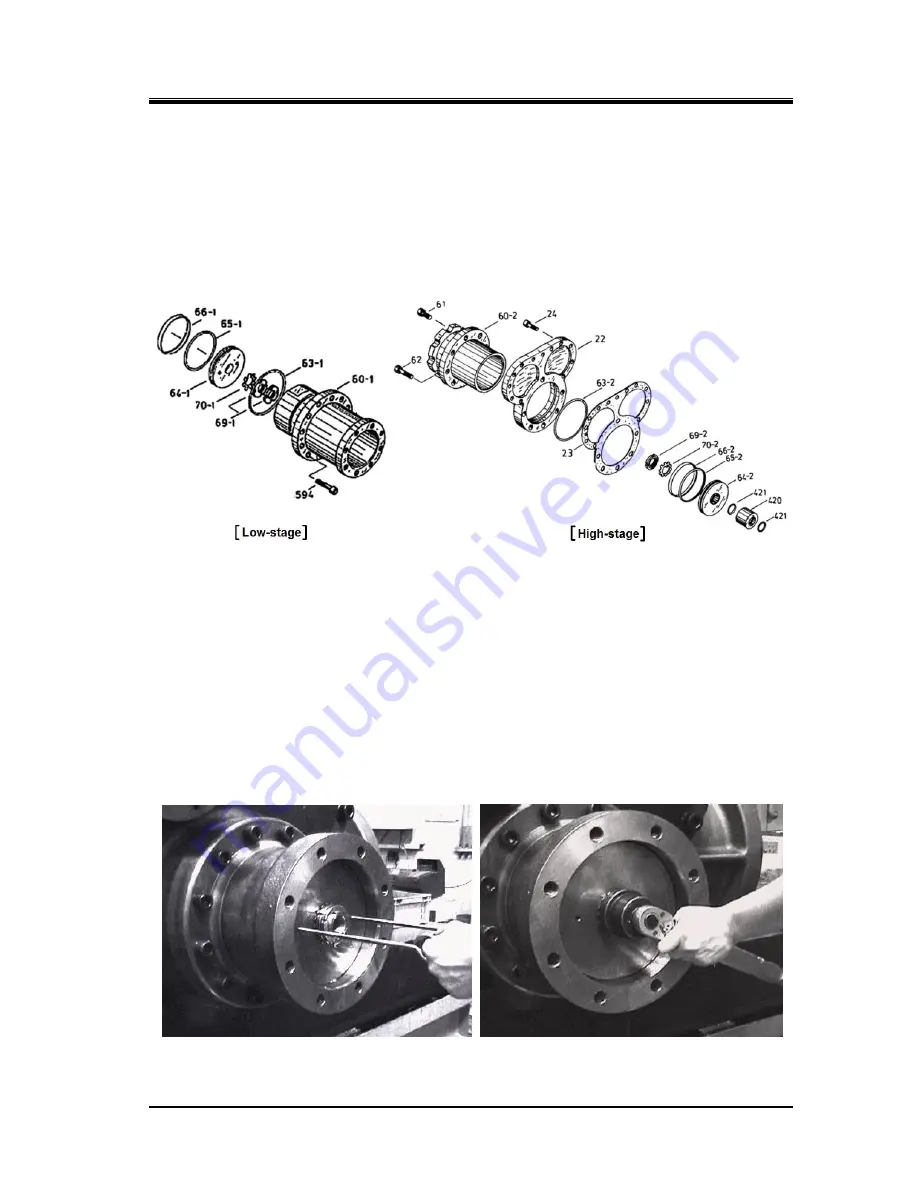

5.4.3

Unloader Piston and Unloader Cylinder

Inside the unloader cylinder [60-1] [60-2] is an unloader piston [64-1] [64-2] around which the cap seal

[66-1] [66-2] and O-ring [65-1] [65-2] are fitted. The unloader piston is assembled to the unloader push

rod [67-1] [67-2], which operates the unloader slide valve, with the lock nut [69-1] [69-2].

Note that the low-stage lock nut [69-1] has a double nut arrangement, and that in the high-stage

unloader cylinder 30 % (indicated load) unloader spacer is installed to prevent an abnormally high

intermediate pressure at the time of compressor start-up.

Figure 5-6 Unloader Cylinder Block

5.4.3.1

Disassembly

a) Screw two M8 eyebolts in the thread holes of the unloader piston, and pull the unloader piston

[64-1] [64-2] fully towards you.

b) Since the low-stage lock nut [69-1] fixing the unloader piston on the unloader push rod has a

double nut arrangement, loosen and remove the front side nut by using a lock nut wrench.

c) Then, release the locking teeth of the lock washer [70-1] [70-2], such that the lock nut [69-1] [69-2]

can be turned. Then, loosen the lock nut using a lock nut wrench, and remove it.

d) Pull out the unloader piston using the M8 eye bolts again.