2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 4032**C

5.4 Disassembly and Inspection

5-21

5.4.5

Bearing Cover

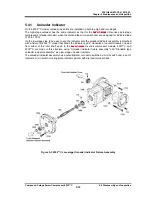

The bearing cover [16] must be removed when the low-stage bearing block is inspected or the rotor is

pulled out for inspection.

5.4.5.1

Disassembly

a) Before starting the work, protect the rotor axis with curing tapes and/or other protective covering

not to damage them.

b) Unscrew and remove 22 in all the hexagon socket head cap screws with captive washer [18-1].

c) Instead of removed bolts, screw in two stud bolts (as shown white arrows in following picture) to top

two thread holes on the bearing head for safety.

d) Screw two eyebolts into the thread holes on the upper bearing cover, and keep lifting using lifting

tools and a crane or like tools.

e) From the back facing holes on the bearing cover flange surface removed the unloader cylinder,

unscrew and remove ten hexagon head cap screws [595A] and two screws [595B] that fasten the

bearing cover to the bearing head [11-1].

Even if remove all fastening bolts, the bearing cover is attached to the bearing head by two

alignment pins [19-1].

f) There are two jacking screw holes in the opposite positions of the bearing head. By screwing in

two left and right M8 eye bolts evenly, the bearing cover will be separated from the bearing head.

When some gap is observed between them, use a thin scraper to remove one side of the gasket

[17-1] from the body.

g) Further screwing in the eye bolts will disengage the bearing cover from the alignment pins.

Figure 5-10 Bearing Cover