2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 4032**C

5.4 Disassembly and Inspection

5-22

5.4.6

Separating High-stage and Low-stage Blocks

The high-stage and low-stage blocks must be separated before inspecting the gear coupling,

high-stage thrust bearing, main bearing, pulled out rotor, etc.

As explained at the beginning of Section 5.5 of this chapter, the separation may be done at the initial

stage of the overhaul work.

5.4.6.1

Disassembly

a) As it is explained in the Section 5.3.5

, the bolts on the bottom side must be removed by

placing the compressor on a special stand before starting the disassembly work.

b) Remove the hexagon socket head cap screws [18-2] that fasten the high-stage bearing head [11-2]

to the low-stage suction cover [5-1].

c) As the gasket [17-2] is sticking to both surfaces of the

high-stage bearing head and the low-stage suction

cover, use the bolts [18-2] that have been removed to

screw them into the jacking threads in the bearing

head to evenly push the suction cover to separate the

two blocks.

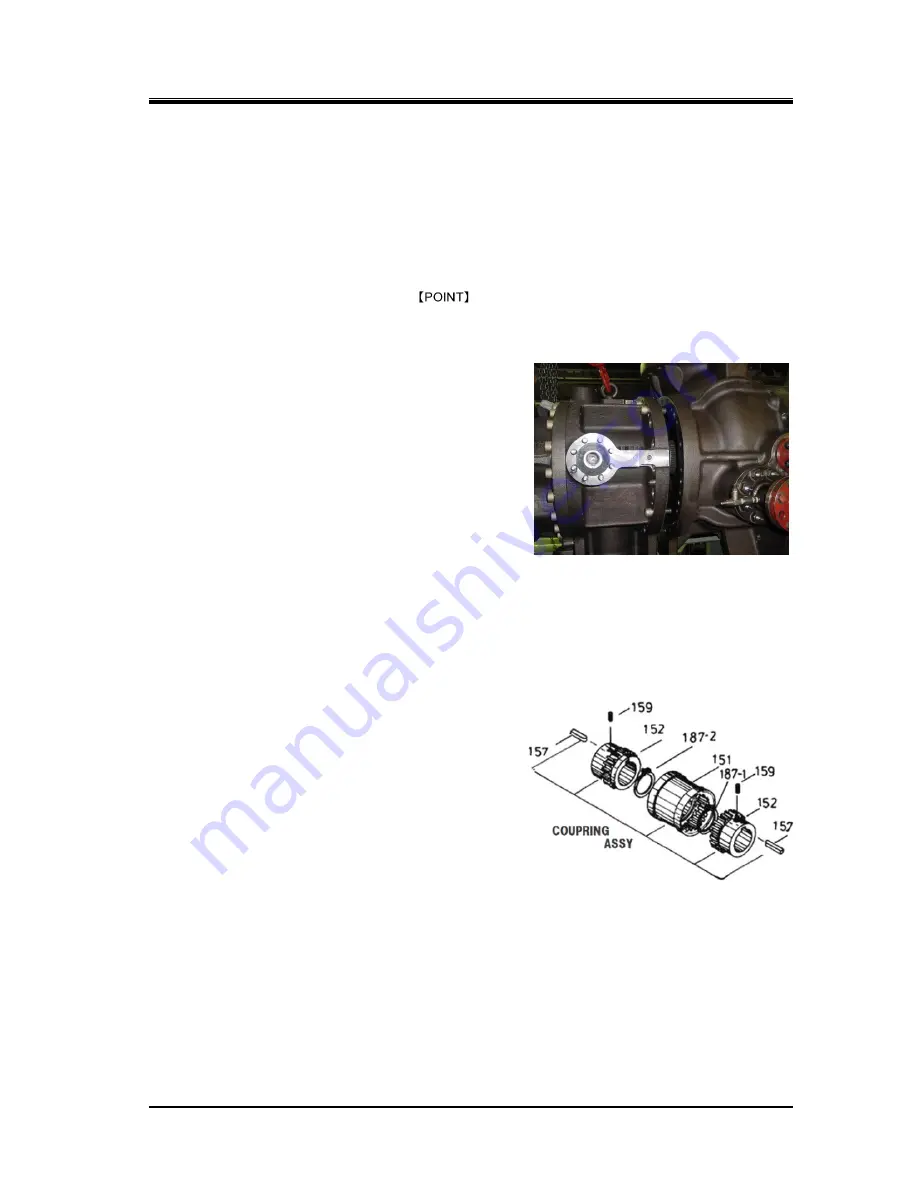

d) The gear coupling assembly [151 to 161] for power

transmission is located inside, on the side of the M

rotor shaft.

As the drive side and driven side of the coupling can be

separated along the shaft axis, move the main body

exactly along the shaft axis to separate them.

5.4.7

Gear Coupling

The gear coupling, which is used as a power transmission means, is divided into the high-stage side

and the low-stage side blocks, with each block attached to the corresponding M rotor shaft, and these

two blocks are directly connected by a drive sleeve.

5.4.7.1

Disassembly

a) The drive sleeve [151] can be removed by hand

after the high-stage and low-stage are separated.

b) Both high-stage and low-stage, remove the snap

ring [18-2] [18-1] that fix the drive hubs [152]

using a external snap ring pliers.

c) Both high-stage and low-stage, loosen and remove

the knurled cup point socket set screws [159] from

the drive hubs used for locking keys [157].

This set screw [159] has been redesigned to the

M10

×

16 with looseness preventing from the M10

×

25 in January 2005.

d) Both high-stage and low-stage, there are two screw holes in the drive hub. Screw M8 eye bolts into

these screw holes and pull out the drive hub. It can be easily pulled out, as clearance fit is used.

5.4.7.2

Inspection

Check the hub and sleeve for possible deformation of the gear teeth and wear on each tooth flank.

If it is found abnormal, replace the whole gear coupling assembly. At the same time, investigate the

cause of the abnormality.

Figure 5-11 Gear Coupling Block