2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 4032**C

5.4 Disassembly and Inspection

5-23

5.4.8

Balance Piston

During the operation of a screw compressor, both the

rotation rate and the thrust load of the M rotor are higher

than those of the F rotor. Accordingly, the service life of

the thrust bearing for the M rotor will be significantly

shorter than that of the F rotor, if no special measures are

taken. As such, in order to reduce the thrust bearing load

on the M rotor side, a hydraulic piston is used on the shaft

end of the rotor drive shaft to cancel the load.

◆

Note that no balance piston is used on the low-stage.

Because the low-stage pressure condition is lower

than high-stage, the service life difference of the bearings

is not so significant compared to the high-stage.

5.4.8.1

Disassembly

a) Remove the snap ring [32] retaining the balance

piston [30] on the shaft using external snap ring pliers.

b) Pull the balance piston straight out by screwing two

eye bolts into the threaded holes. While the rotor shaft

has a balance piston key [31], it is unnecessary to

remove the key.

In addition, to prevent rotation of the balance piston

sleeve [33], spring pin [34] is used in this models, it is

unnecessary to remove the pin.

c) Remove the snap ring [37] securing the balance

piston sleeve using the internal snap ring pliers.

As the snap ring is pressed out by the internal O-ring

[35], slightly pushing it can easily remove the snap ring.

d) Remove the balance piston sleeve and O-ring.

As clearance fit is used to engage the outside of the sleeve with the suction cover, you can easily

pull it out.

As there is an O-ring spacer [36], also remove the spacer.

5.4.8.2

Inspection

While you will be able to find some trace of wear on the inside surface of the balance piston sleeve,

such wear is not abnormal as it is caused because the clearance between the balance piston and the

sleeve is narrower than the clearance between the rotor shaft and the bearing.

Because enough clearance is given to the outside of balance piston sleeve in order not to apply the

bearing load to the balance piston, no further development of the wear is expected.

However, you should still carefully check the condition because when the side bearing is significantly

worn, the balance piston may also be worn.

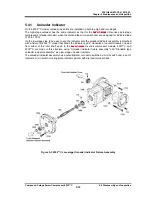

Figure 5-12 Balance Piston Block