2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor 4032**C

5.4 Disassembly and Inspection

5-28

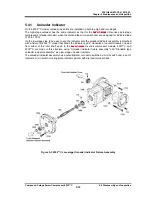

5.4.11.2

Disassembly of the Low-stage Thrust Bearing Block

a) Remove the lock nut [39-1] that has been

loosened. Then, remove the torsional slip

washer [237-1], lock washer [40-1], and

thrust washer [250-1].

b) Remove the key [346] for TPTB (Tilting Pad

Thrust Bearing) on the rotor shaft. This key

is easy to lose because it is small. Take care

not to lose.

c) Screw two eyebolts into the TPTB and pull it

out straight along the rotor shaft until the

screw hole for eyebolt comes out (following

picture to the left).

d) Attach the lifting eyebolt on the top of the

TPTB and pull out it along the rotor shaft

using a lifting device (picture in the middle

below).

e) Remove the thrust bearing alignment spacer [42-1] (following picture to the right).

5.4.11.3 Inspection

High-stage Ball Bearing

a) The thrust bearing is normal if the bearing balls are found fully glossy after the thrust bearing has

been fully washed and cleaned. It is abnormal if the ball surface has tarnish or streaky pattern.

b) Support the inner race with your hand and rotate the outer race. If you feel abnormal vibration on

the hand, the rolling contact surface of the inner or outer race or some balls may be in an abnormal

condition. So, carefully check the conditions. You could feel some irregular click even with a small f

foreign matter that has entered during the removal process. In such a case, it should return to the

normal condition when high pressure air is used to blow out the foreign matters after washing and

cleaning the unit. If the bearing is determined to be defective, it must be replaced with new ones.

c) If the inner race and outer race can be easily separated, the wear is considered excessive. If so,

you cannot reuse the bearing.

d) After washing the bearing, you should be able to hear a clattering sound when the bearing is

rotated by hand. Such a sound is due to the motion of the ball within the backlash or play, or the

gap between the retainer and the ball. Such a sound will not be heard if the bearing is held

horizontal and turned. If some lubricating oil is applied after washing the bearing, the sound should

not be heard when the bearing is turned. If you can still hear the sound, the bearing is abnormal.

e) If any abnormality is seen in the thrust bearing in the above inspection, replace with new ones.

In addition, carefully check the reason whether due to mere aging or any problem with the

operating condition and/or lubricating mechanism.

If the compressor has been operated for more than 20000 hours without replacing the thrust

bearing, it is recommended to replace the bearing with a new one for safely continuing the

operation until the next overhaul, even if no abnormality is found in the above described inspection.

Figure 5-14 Low-stage Thrust Bearing Block