2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-41

5.5.6 Installing the Suction Cover

Both of the high-stage and low-stage suction cover

gaskets [6] are not symmetrically shaped.

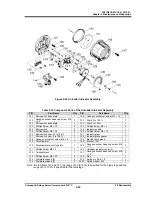

Also, as shown in Figure 5-19, there are three type

gaskets in the same sizing. Be careful not to use a wrong

gasket.

After the design modification in June 2008, the tabs have

been added on the suction cover gasket for identifying

the left/right and the applicable model

a) Apply sufficient oil on both sides of the gasket,

confirm the oil supply/return holes position and put

the gasket on the main rotor casing.

b) At first on the high-stage, pass the unloader push rod

through the hole at the bottom of the suction cover

[5-2].

Slide (or use a lifting device to move) the suction

cover in parallel along the shaft axis to engage the

rotor shafts with the side bearings. At this time, be

careful not to damage the inside surface of the side

bearing by the shaft end.

As the low-stage unloader push rod is out to

the bearing head side, be careful only with the

rotor shaft end in this work.

c) After the suction cover has been pushed in up

to the flange surface, lightly fasten some of the

bolts [2].

d) Using a copper hammer or an aluminum

hammer, drive in the alignment pins [3].

e) Tighten the hexagon socket head cap screws

evenly up to the specified tightening torque.

The bolts on the bottom side (about 6 bolts) are to be tightened during the final assembly stage, on

the special stand used in the disassembly process.

f)

For both the high-stage and low-stage blocks, move the unloader push rod back and force by hand

to check that it is working normally.

g) Hold and rotate the M rotor shaft to check if it works normally.

In addition, check that the rotor has an axial play (i.e., the rotor can move in the axial direction).

Figure 5-19 Suction Cover Gasket