2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-46

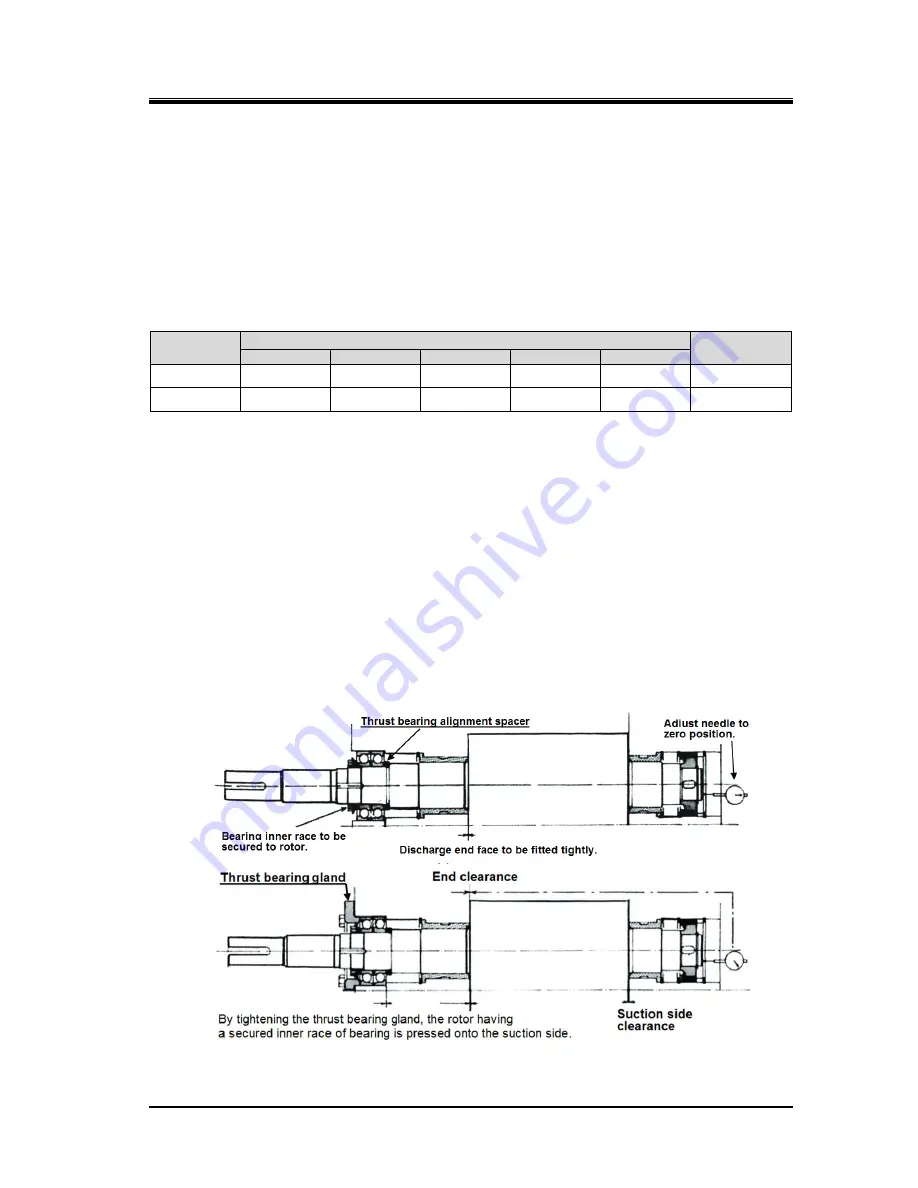

5.5.8.3 End Clearance Measurement

At this point (i.e., after the thrust bearing block has been fully assembled), measure the clearance

between the bearing head end face and the rotor end face on the discharge side. This clearance is

called as the end clearance.

There is no difference between the TPTB and the ball bearing specifications in the manner of end

clearance measurement and adjustment.

If the measured clearance does not satisfy the range specified in Table 5-11, proper adjustment must

be made.

Table 5-11 Specified Limits of End Clearance

End Clearance

(mm)

Tightening

Torque (N

・

m)

S

M

L

LL

XL

High-stage

O.17 to 0.21

0.20 to 0.24

0.23 to 0.27

0.26 to 0.30

-

90

Low-stage

O.70 to 0.80

0.75 to 0.85

0.80 to 0.90

0.85 to 0.95

0.80 to 1.00

120

a) Pressing the rotor shaft on to the discharge side with securing the thrust bearing to the rotor shaft.

In case of the high-stage, the rotor can be pushed to the discharge side by tapping with cushion

like Teflon block, not striking the rotor shaft end directly, but the same method cannot be applied to

the low-stage.

Manufacturing and preparing a jacking bolt to press the rotor shaft end face from the suction side

and its supporting jig (i.e., a steel plate with about 15 mm thickness and threaded hole at the

position of the rotor end face, fixing to two opposite positions bolt holes of the suction cover flange)

will make this pressing work easier.

b) Prepare the thrust bearing gland to be readily mounted. Mount a dial gauge on the axial end of the

rotor, and set the indication needle to zero point while the rotor is fully pressed onto the discharge

end face.

c) Without inserting the (conical) spring washer [46] and the O-ring [150], tighten the fastening bolts of

the bearing gland sequentially and evenly up to the specified tightening torque.

In case of the TPTB, align the notch of the thrust bearing gland to the protrusion of the TPTB.

Tightening each bolt at once at the specified torque must be avoided because it will result in

uneven tightening. So, repeat to sequentially tighten the bolts for several times.

Figure 5-21 End Clearance Measurement