2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-48

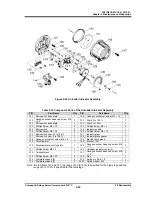

5.5.9 Balance Piston Cover and High-stage Unloader Cylinder

a) Install the unload spacer [420] attached two O-rings [421] in the inner circumference grooves on

the high-stage unloader push rod [67-2].

This unload spacer is used as high-stage load capacity adjustment (minimum 30 % load) to

prevent overload of the driving machine at the time of compressor start-up.

b) Install the unloader cylinder [60-2] on the balance piston cover [22] and then install the resulting

assembly on the high-stage suction cover [5-2].

However the balance piston cover and the unloader cylinder are often not disassembled, so

following procedures c) to f) are applied to the case that this block has disassembled.

c) Attach the O-ring [63-2] in the O-ring groove on the machined surface of the balance piston cover

along which the unloader cylinder is installed.

d) Align the position of the balance piston cover with the unloader cylinder. As no gasket is used on

the mating flange between the balance piston cover and unloader cylinder, evenly and thinly apply

liquid gasket (made of special synthetic rubber) on the surface of the flange of the unloader

cylinder inside from the center of the bolt holes.

e) As the O-ring of the balance piston cover is already installed, lightly tap the flange surface with a

soft hammer to install it.

f)

When joining the flanges, also align the bolt hole positions. Then, insert two hexagon socket head

cap screws [61] in the positions near the 10:10 of clock to tighten the unloader cylinder to the

balance piston cover.

g) Confirm the O-ring [73-2] is attached in the O-ring groove on the tip of the unloader push rod [67-2],

at the position where the unloader piston is installed.

h) Attach the O-ring [65-2] without lubricating oil on the unloader piston [64-2], and then install the cap

seal [66-2] on it. It can be smoothly installed by slightly folding the cap seal along the

circumferential direction. Also, using a small and smooth spatula will facilitate the assembling work.

i) Install the unloader piston fitted with the O-ring and cap seal in the unloader cylinder. One side of

the unloader piston is with screw holes for eye bolts, while the other side does not have such holes.

First, to make it easier to fit the cap seal on the unloader cylinder wall, lightly press one side of the

piston onto the chamfered area of the unloader cylinder by hand, changing the side of the piston

for several times. Finally, apply lubricating oil to the unloader cylinder, then, push and install the

piston with the screw holes side of the piston facing the unloader cover. After the installation, check

that the cap seal is not broken or pinched.

j) Push the unloader piston into the unloader cylinder and set it in the middle of the cylinder, pull the

unloader push rod [67-2] toward you.

k) Apply sufficient amount of oil to the balance piston cover gasket [23] and attach the gasket on the

balance piston cover flange surface. Then, lift up the assembly of the balance piston cover and the

unloader cylinder using a crane or like lifting device, and install the assembly onto the high-stage

suction cover.

In the middle, pushing the unloader piston into the push rod and temporarily fastening the lock nut

[69-2] in the course of the work will make later work easier.

m) After joining the flanges together, tighten the hexagon socket head cap screws [24] of the balance

piston cover and tighten the hexagon socket head cap screws [62-2] of the unloader cylinder at

each specified torque.

n) Use the eye bolts to pull the piston toward you, once remove the temporarily fastened lock nut,

install the lock washer [70-2] and lock nut [69-2], and then tighten the lock nut at the specified

torque. To prevent loosening, bend the tooth of the lock washer at the notch of the lock nut.

Lastly, use the eye bolts to check the smooth movement of the piston.