2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-50

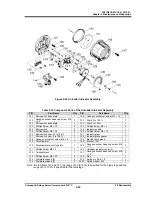

5.5.12 Low-stage Unloader Cylinder

The installation of the low-stage unloader cylinder may be done either after the bearing cover

installation described in Section 5.5.10 or after the assembly of the shaft seal block.

a) Check that the O-ring [73-1] is inserted in the O-ring groove on the tip of the unloader push rod

[67-1], at the position where the unloader piston is installed.

b) Install the O-ring [65-1] and cap seal [66-1] on the unloader piston [64-1].

c) Install the unloader piston fitted with the O-ring and cap seal in the unloader cylinder [60-1]. The

work procedure is the same as that for the high-stage side as described in Section 5.5.9, item i).

d) In case of 4032**C, the O-ring [63-1] for sealing between the bearing cover [16] and the unloader

cylinder is installed on the O-ring groove in the unloader cylinder.

e) Install the unloader cylinder into the bearing cover, and fasten the twelve hexagon socket head cap

screws [594] evenly at the specified tightening torque.

f) Set the lock washer [70-1] and lock nut [69-1] on the unloader push rod, and fasten the lock nut at

the specified torque using a lock nut wrench.

To prevent loosening, align the positions of the lock washer

’s tooth and the notched part of the lock

nut, and bend the lock washer

’s tooth.

Lastly, use the eye bolts to check the movement of the unloader piston.