2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-51

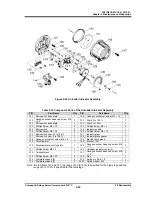

5.5.13 Unloader Cover

[Low-stage] [High-stage]

Figure 5-23 Unloader Cover Block

a) Use eye bolts to move the unloader piston back and forth to check the normal operation again.

b) Assemble the ball bearing [78] on the shaft portion of the indicator cam [77]. When fitting the

bearing onto the shaft, push the inner race of the bearing. Pushing the outer race may damage the

bearing. Push the bearing to the stepped portion of the indicator cam and retain the bearing with

the external snap ring.

c) Sufficiently apply oil on the unloader cover [74], and install the V-ring set [82] in it. One of the rings

of the V-ring set (i.e., dark colored one) is made of rubber to improve the sealing performance, and

is placed as the second item from the outside. The orientation of the V-ring must be such that the

apex of the V-shape faces the outside and the lips face inside.

d) Install the spring [83] and the spring retainer [84] into position. Then, insert the shaft of the indicator

cam assembled in Step b) above into the V-ring. Lastly, fasten three hexagon socket head cap

screws [81] to tighten the bearing gland [80] onto the unloader cover to retain the bearing.

In case of 4032**C low-stage, the spring washers [597] are required for the hexagon

socket head cap screws [81] tightening the bearing gland [80]. Be careful not to

forget setting the spring washer.

e) After making sure that the indicator cam rotates smoothly, attach the O-ring [75] to the unloader

cover.

f) Install the unloader cover on the unloader cylinder [60]. Making sure that the guide pin [68] of the

unloader push rod [67] is well engaged in the spiral groove of the indicator cam, push-in the

unloader cover.

With the oil supply hole for the unloader operation up, secure the unloader cover by fastening the

hexagon socket head cap screws [76] at the specified torque.