2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

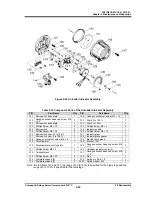

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-53

5.5.15 Unloader Indicator

The unloader indicator is implemented with two micro-switches, a micro-switch cam, and a

potentiometer. These parts are used to detect the change in the rotation angle of the indicator cam

shaft, which converts the axial position change of the unloader slide valve into rotational position

change, convert the change into an electric signal, and send the signal to the package unit and/or the

controller of the refrigeration system.

To check the unloader indicator after inspection, adjustment, or parts replacement, coordination with

the controller side will be required. Even in a case where the compressor is carried out of the

installation site for overhaul, the indicator assembly is often removed from the compressor (to be kept

at the site) and the inspection/adjustment and parts replacement are performed at the site. Thus, this

section provides a detailed procedure, which may be helpful after the reassembly work.

When removing the indicator block or performing inspection/adjustment or parts

replacement, be sure to shut down the control power and use lock-out and tag-out

procedures. If the power is not shut down, there is a risk of electric shock.

The high-stage of 4032**C is implemented with an indicator assembly that is identical to the one used

in a

standard single stage compressor (except that the dial and micro-switch cam which are

exclusively designed for 4032**C high-stage, for the range of 30 to 100 %).

On the low-stage of 4032**C, a standard indicator assembly is mounted on the special fixture for

4032**C low-stage that converts the axial direction of the indicator assembly to the lateral direction.

5.5.15.1 Potentiometer

The potentiometer [129] of the standard type indicator is a rotary instrument for measurement over a

full turn.

It senses the continuously variable position (indicated load of 0% to 100%) of the unloader slide valve,

and feeds the sensed position as electric signals to the control side of the package unit or refrigerating

system.

While the expected service life of the potentiometer will significantly vary depending on the installation

environment of the compressor (e.g. corrosive gas atmosphere, moisture, etc.) and operational

conditions (e.g. frequent partial load operations, frequent start/stop operation, vibration, etc.), the

potentiometer is a consumable part that requires regular replacement according to the situation.

■

Disassembly

Refer to Section 5.4.1 in this manual for the low-stage/high-stage disassembly procedure.

■

Inspection

a) Check at the terminal block that the lead wires of the potentiometer are not loosened.

b) Check for any crack or other defects in the soldering of the lead wires of the potentiometer.

c) Manually rotate the shaft of the potentiometer and measure the resistance value using a circuit

tester to check that the resistance value changes smoothly.