2200M4JE-HO-iS2-N_2014.04.

Chapter 5 Maintenance and Inspection

Screw Compressor i-series

5.2 Maintenance and Inspection List

5-5

5.2.3 Guidelines for Compressor Overhaul Interval

When servicing or overhauling the compressor, follow the instructions and guidelines described below.

The compressor overhaul interval is largely affected by the compressor operating conditions, type and

status of refrigerant and oil, and the system/equipment in which the compressor is operated. The table

below lists overhaul intervals recommended by MAYEKAWA which are categorized based on the

compressor operating conditions.

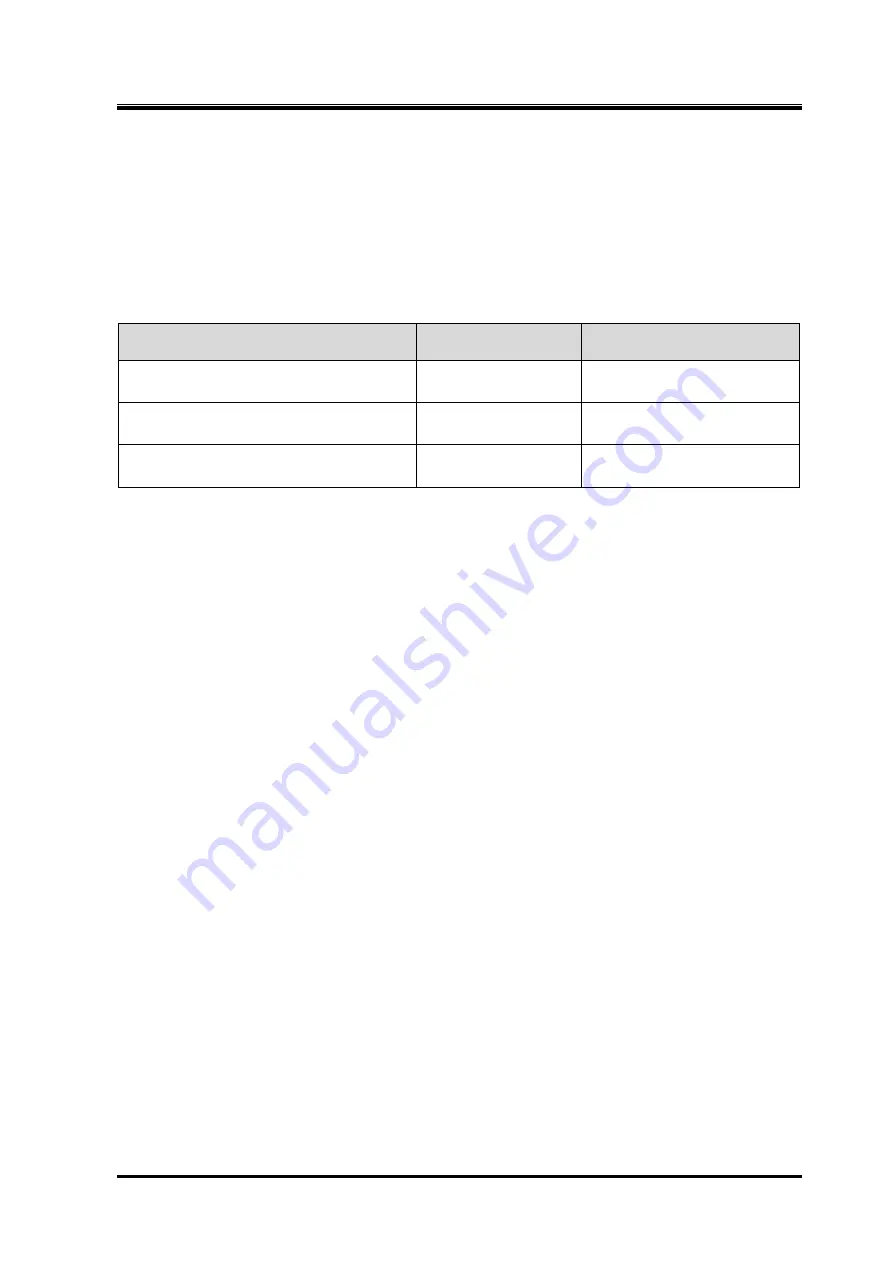

Table 5-4

Standard Package Operation Conditions and Overhaul Interval Guidelines

Category of operating condition

Application example

Recommended Overhaul

Interval

Relatively stable operating condition

Refrigeration and cold

storage

Every 5 years or 40,000

operating hours

Relatively changing operating condition

Ice maker/chiller

Every 4 years or 30,000

operating hours

Frequently started/stopped, and relatively

changing operating condition

Heat pump

Every 3 years or 20,000

operating hours

Note 1: The above guidelines are only applicable when the compressor is operated within the operation

limits specified separately.

(Refer to section 2.3.2 "Operation Limits" in this manual.)

Note 2: The above guidelines are only applicable when the compressor undergoes daily and periodic

inspections specified separately.

(Refer to section 5.2.1 "Daily Management" in this manual.)

Note 3: Inspect the compressor at the intervals of specified period or operating hours, whichever comes

first.

Note 4: The above guidelines do not constitute any warranty.