2200M4JE-HO-iS2-N_2014.04.

Chapter 5 Maintenance and Inspection

Screw Compressor i-series

5.4 Compressor Disassembly Preparation

5-9

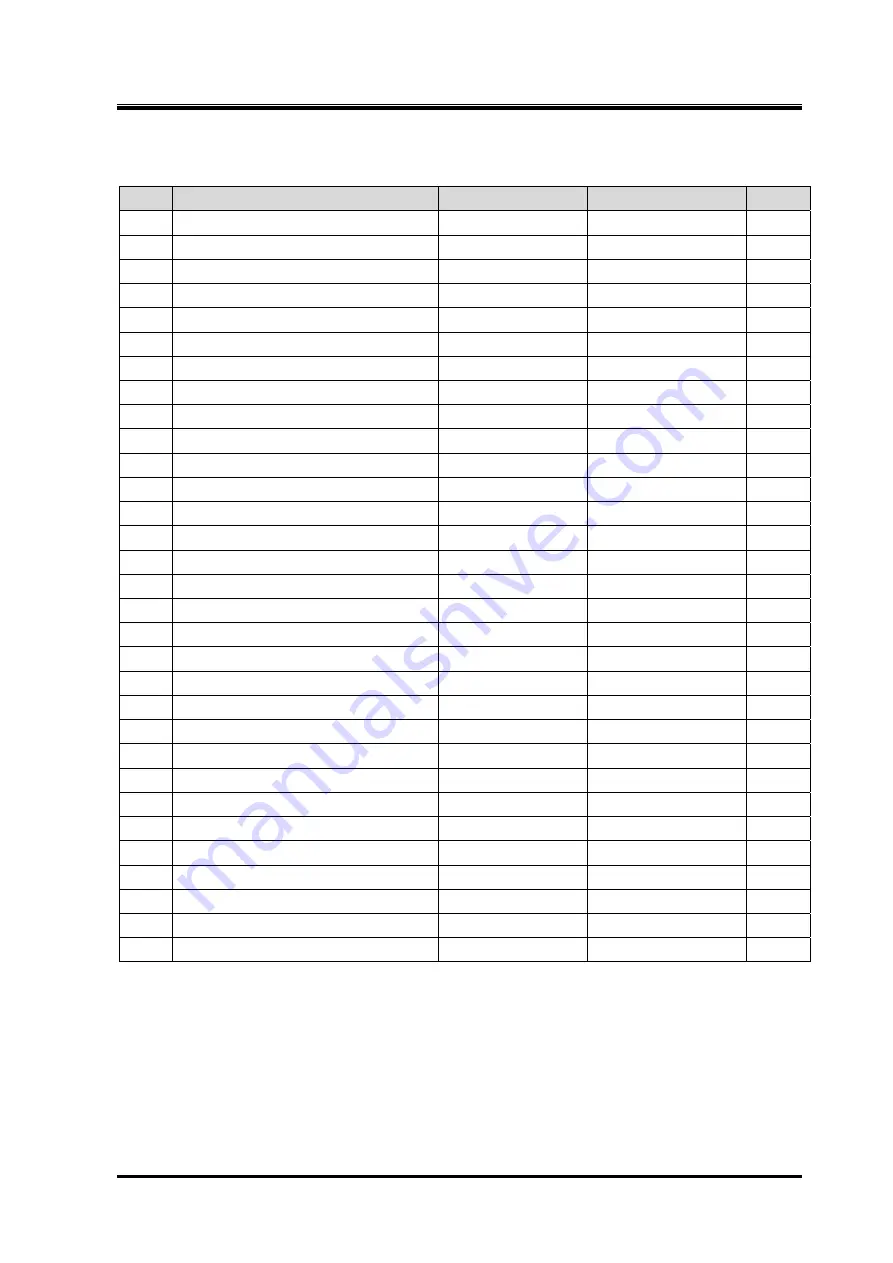

Table 5-8 List of replacement parts of i160

No.

Part name

Code No.

Remarks

Qty

6

Gasket, Strainer Cover

CS00900-I160

i160 t=0.5

2

7-1

O-ring

see Note 1

PA12-150

JIS B 2401 G150

1

7-2

O-ring

see Note 1

PA12-140

JIS B 2401 G140

1

12

Gasket, Bearing Head

CS01200-I160

i160 t=0.5

1

17

Gasket, Bearing Cover

CS01700-I160

i160 t=0.5

1

23

Gasket, End Cover

CS02300-I160N

i160 t=1.0

1

27-1

Radial Bearing M

CS02800-FM160M

FM160

2

27-2

Radial Bearing F

CS02800-FM160F

FM160

2

30

Balance Piston

see Note 2

CS03000-I160

i160

1

33

Sleeve, Balance Piston

see Note 2

CS03300-I160

i160

1

35

O-ring

see Note 1

PA11-024

JIS B2401 P24

2

38-1

Thrust Bearing M

CS03800-I160M

7311B

1

38-2

Thrust Bearing F

CS03800-I160F

7312B

1

40-1

Lock Washer

NG32-011

AW11

1

40-2

Lock Washer

NG32-012

AW12

1

49

O-ring

see Note 1

PA12-090

JIS B 2401 G90

1

50

Oil Seal

see Note 2

CS05000-160VD

160*** (S55×70×9)

1

52

Gasket, Seal Cover

CS05200-160N

160*** t=0.5

1

93

Gasket, Suction Flange

PL300-125

ANSI 300 # 5"

1

96

Gasket, Discharge Flange

PL300-080

ANSI 300 # 3"

1

100

Mechanical Seal Assembly

see Note 3

CS10002-160EBS

160V BBSE

1set

150-1

O-ring

see Note 1

PA12-110

JIS B 2401 G110

1

150-2

O-ring

see Note 1

PA12-115

JIS B 2401 G115

1

216-2

Flange Gasket, Oil Inlet Port

CR72000-025N

MYCOM 25A

1

237-1

Torsional Slip Washer M

CS23700-FM160M

FM160

1

237-2

Torsional Slip Washer F

CS23700-160

160***

1

395

Gasket, Unloader Cover

CS39500-I160

i160 t=1.0

2

480

Strainer Element

see Note 2

CS48000-I160

i160 #150

Φ

160×200

1

489

Valve Seat

CS48900-I160

i160

1

491

Check Valve Shaft

see Note 2

CS49100-I160

i160

1

495

O-ring

see Note 1

PA11-007

JIS B 2401 P7

1

Note 1:

The part code of the O-ring is the one assigned to NBR-70-1 which is standard material.

Note 2:

When checking each part (No.30, 33, 50, 480, 491) and in case of malfunction's being a little

seen, that it is possible to replace, prepare beforehand. If a special malfunction is not seen, it is

possible to use in the continuation.

Note 3:

Mechanical seal assembly (No.100) should be replaced if any defect is found during inspection.

Actually, however, it is sometimes difficult to find out defects on the sliding surface only through visual

inspection. In such circumstances, MAYEKAWA recommends to replace it with a new one.

Also, if it is difficult to stop the compressor operation except for scheduled inspections, MAYEKAWA

recommends replacing No.100 in the same way.