2200M4JE-HO-iS2-N_2014.04.

Screw Compressor i-series

Appendix -3

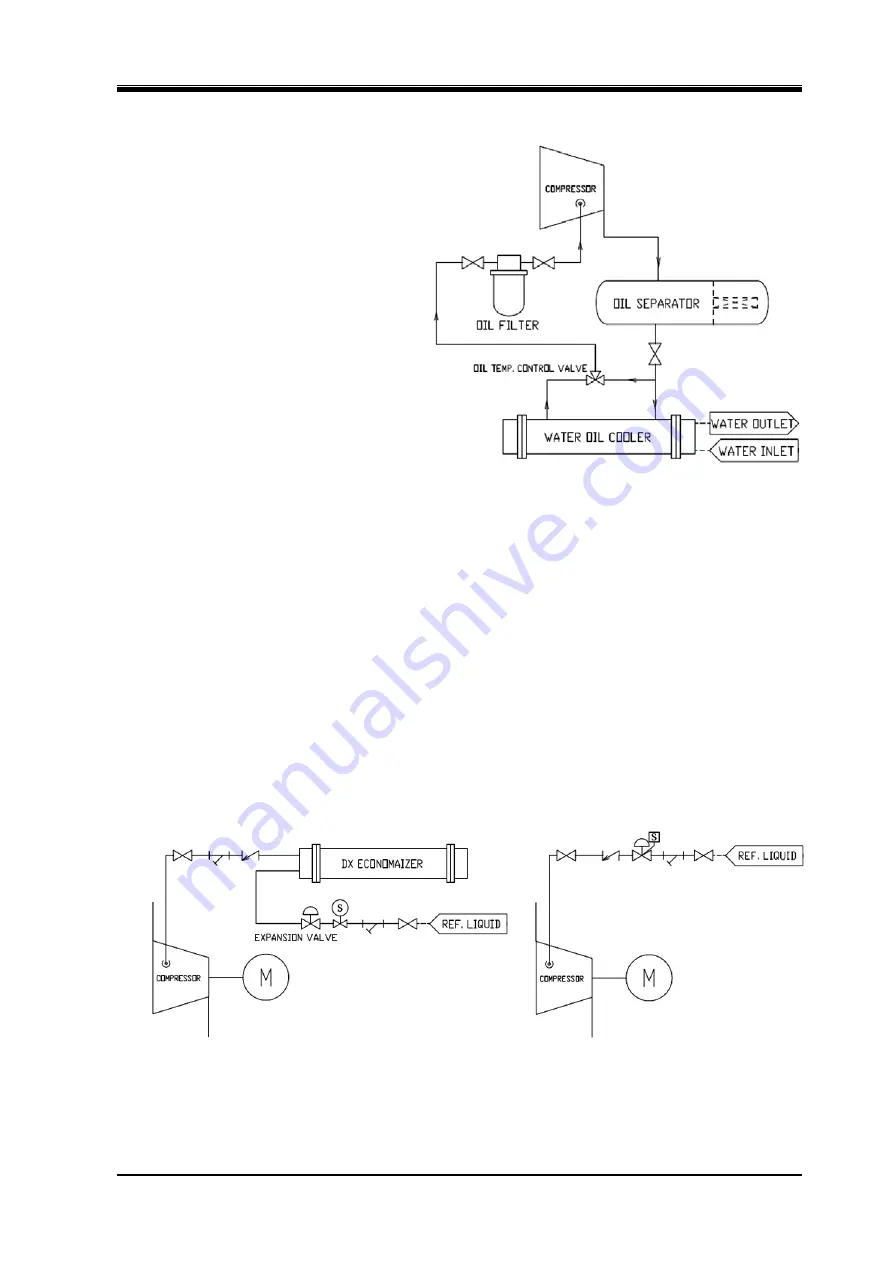

Oil Temperature Control

Generally, in order to keep the lubricant

temperature in the oil separator, install

the oil heater at the bottom of the oil

separator.

In the cold district, the viscosity of

lubricant at the compressor start-up is

decreased; lubricant is hard to flow, so

there are cases that package unit

cannot secure the necessary oil supply

pressure.

When you need to secure the oil supply

temperature to the compressor, install

an oil temperature control valve.

Figure app.-5 is a reference flow in oil

temperature control valve use.

The mixing -type three-way valve is

general.

Figure app.-5

Economizer

i-series compressor has a economizer port for improvement of refrigerating effect.

Figure app.-6 is a use example of the general economizer system with the i-series compressor

package unit.

DX type composed by a expansion valve and a heat exchanger, and flash tank type inhaling from

common flash tank are general.

Install a filter with the ability for filtration less than 100

μ

m in the economizer line

。

In the case of DX type economizer, type of the heat exchanger can choose with shell and tube type,

plate type, etc. Use it properly by the system of refrigerator.

I

In addition, the economizer port can also be used as a side load gas inlet port, but since the

diameter is small compared to general port for side load port, please contact us for the details.

DX type

Flash tank type

Figure app.-6