114061H System Installation Manual

11

5. Write down the circuit breaker value that applies to your system from Table 5.1:

__________

6. Now, look at Table 5.2 below, and use the notes below to find the proper gauge wire

for the recommended circuit breaker recorded in step 5.

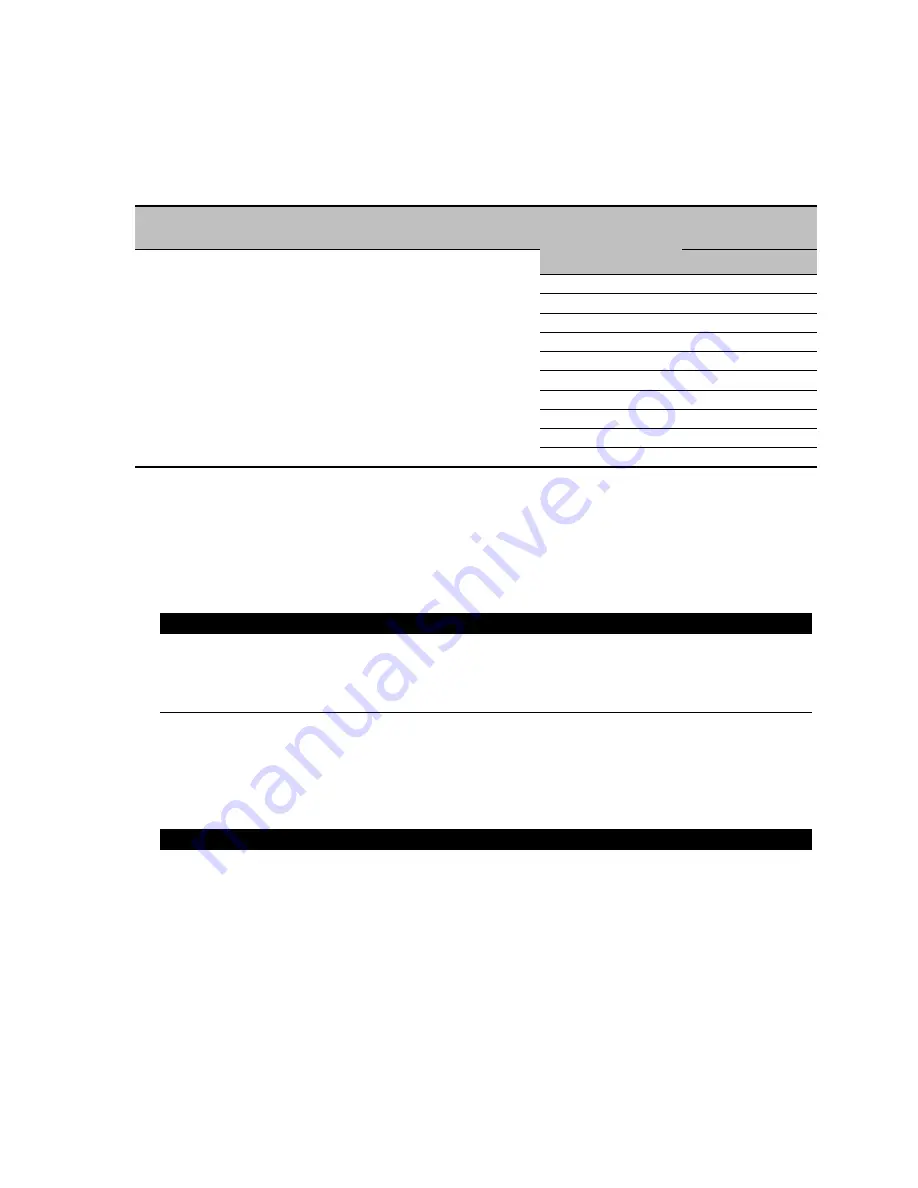

Table 5.2 Recommended Minimum Wire Sizes

Read These Important Notes!

For this Input

Circuit Breaker

Size...

Use this Size 90°C

Copper Wire

This table lists the AWG and mm2 wire size for each circuit breaker size.

The minimum recommended circuit breaker sizes for each model and

voltage application are listed in Table 5.1. The temperature rating of

conductor must not be less than 90° C wire. Based on the ampacities

given in Tables 310-16 of the National Electrical Code, ANSI/NFPA 70-

1993 (Table 2 of the CEC), and NEC article 220 (CEC Section 4). Circuit

conductors, must be the same size (ampacity) wires and equipment-

grounding conductors must meet Table 250-95 of the National Electrical

Code. Code may require a larger wire size than shown in this table

because of temperature, number of conductors in the conduit, or long

service runs. Follow local code requirements.

AWG

Mm2

10, 15, 20

12

3.31

25, 30

10

5.26

35, 40, 45

8

8.36

50, 60

6

13.30

70, 80

4

21.15

90, 100

2

33.62

110

1

42.11

125

1/0

53.49

150, 175

3/0

67.43

225

4/0

74.40

7. The input circuit breaker in the input service panel provides the means for disconnecting AC

to the unit. Only authorized persons shall be able to disconnect AC to the unit [see NEC 700-20

and 700-21(CEC Section 46)]. If you are using the input circuit breaker to disconnect AC, you

must make sure that only authorized persons have control of the circuit breaker panel to meet

the requirements of NEC 700-20 (CEC Section 46).

8

. Read the following caution, before removing conduit knockouts.

CAUTION

To prevent electrical shock or damage to your equipment, the Installation Switch (S1), the Main

AC Input Circuit Breaker (CB1), and the circuit breaker at the input service panel should all be

turned off. The Main DC Battery Fuse and the Battery Disconnect Fuse(s) (if you have one)

should be removed.

9

. Remove knockouts for AC Input and AC Output in the top or left and right side of the system

(See figure 4.1). AC input conductors and AC output conductors must be installed in separate

conduits, and emergency and non-emergency output circuits must be installed in separate

conduits.

CAUTION

Do not drill the cabinet; drill filings may damage the unit and keep it from operating. If you

need larger knockouts, use a chassis punch to punch out the appropriate knockout. Do not

create additional knockouts

.

10. Install the conduit. You must run the AC input service conductors and AC output conductors

through separate conduits. Emergency output conductors and non-emergency output conductors

must also be run through separate conduits. Emergency output circuits shall be installed in

dedicated conduit systems and not shared with other electrical circuits as described in NEC 700-

9(b) [CEC Section 47-108].