20

Display

Fault

THE AUTOMATION

DOES NOT WORK,

THE DISPLAY IS

OFF

THE DOOR DOES

NOT MOVE

THE CHAIN TURNS

BUT THE DOOR

DOES NOT MOVE

THE ALARM KEEPS

ON SOUNDING

THE DOOR DOES

NOT OPEN NOR

CLOSES, STUCKS

WHEN CLOSING

THE DOOR DOES

NOT WORK

PROPERLY

THE DOOR DOES

NOT MOVE OR

DOES NOT

COMPLETE THE

CYCLE

THE DOOR DOES

NOT MOVE, OR

STOPS, OR

REVERSES

THE DOOR

STREAKS WHEN

OPERATING

THE CHAIN LOST

TENSION AND IT'S

NOISY

THE DOOR

REMAINS OPENED

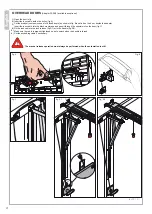

TROUBLE SHOOTING

The control unit is integrated with self-diagnostic feature. Any possible faults will be detected and alerted through the display.

Here below the list of most common faults and solutions.

Cause

• Check the power supply.

• Fuses can be possibly burnt.

• No transmitter has been stored

• Check the transmitter battery charge

• The trolley's clutch may be unlocked

• The chain has come out the cogwheel

Solu

tion

Check the power supply.

Replace the fuses.

Replace the battery.

Lock the clutch (p.7)

Properly lubricate the part between the rail and the clutch.

• Friction between rail and clutch due to waste

Fix the bolt properly on the spring, hold the chain in place and

lubricate it.

• Chain tension reduction due to extended

use without regular lubrication

Follow the installation instructions (p. 5)

Check photocells wiring (p. 15)

• Incorrect photocell wiring

Check the safety microswitch is not crushed.

Release the microswitch that may have been trapped.

• Crushed safety microswitch

• Incorrect photocell wiring

• Permanent obstacle within the photocell

area

Check photocell operation and wiring again

(p.15)

Clear the photocell area.

• Microswitch operating - simple warning

• Possible humidity traces in the electronics

and wires

• Possible oxide traces in motor's wires

• Photocell short circuit

• Fautly microswitch

Remove humidity (qualified personnel only)

Check motor's wiring

Check photocell's wiring (p.15)

Check microswitch' wiring

• Faulty door frame or incorrectly installed

• Faulty motor or motor not wired

• Faulty encoder or not wired

Check the mechanical conditions of the door.

Check the adjustment of springs and counterweights.

Adjust the force settings, p.9 E3.

Reposition the chain on the cogwheel.

• 2000 cycles have been performed

Set limit switches again (p. 8).

• Unproper setting

Adjust counterweights and springs.

• Incorrect balancing of counterweights or

springs

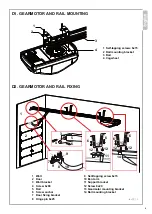

Follow the installation instructions (p. 18)

• Incorrect installation of the boomerang

bracket (for overhead doors only)

• The door is left opened since a while and the

alarm function is activated

Close the door.

Switch the power off and then on again.

Store a new remote control.

Incorrect transmitter selection, review procedure.

• The distance of the tension spring

has not been adjusted

rev0

2

_19