6

1. Using the post bracket as a reference, mark and drill the holes for the post

bracket.

2. Attach the post bracket using the correct fastening material based on

existing installation (building / material substance). Please consult the gate

manufacturer.

3. The slots on the post bracket allow for alignment. When the post bracket is

level tighten the nuts.

1. Using the post bracket as a reference, mark and drill the holes for the post

bracket.

2. Attach the post bracket using the correct fastening material based on

existing installation (building / material substance). Please consult the gate

manufacturer.

3. The slots on the post bracket allow for alignment. When the post bracket is

level tighten the nuts.

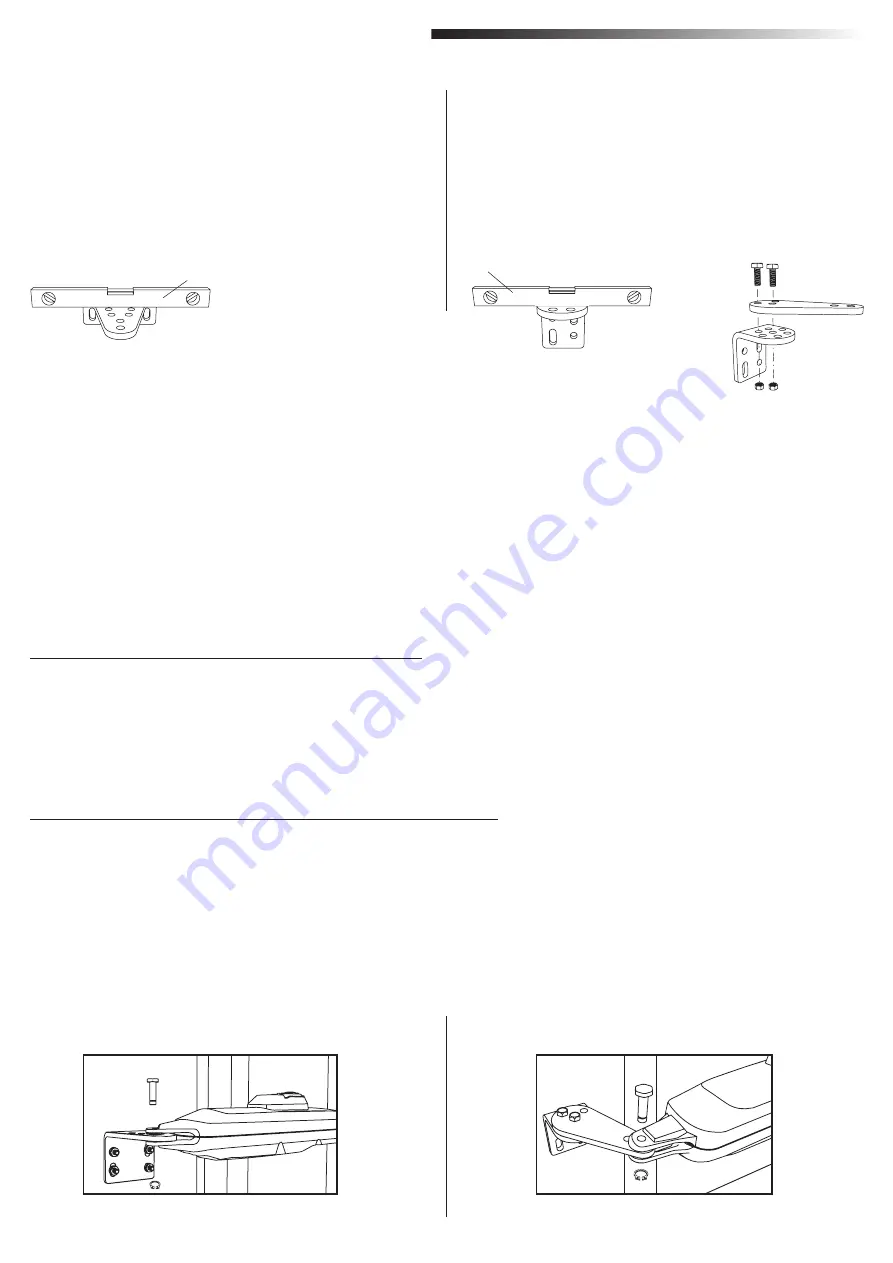

5.4 Operator Mounting and Travel Distance Adjustment

Level

1. Align the holes on the operator to the post bracket holes and connect using the circlip pin and circlip.

2. Release the operator clutch with the release key (see page 8).

3. Bring gate leaf to the CLOSED position.

NOTE:

The system must operate with:

LA250EVK only with external gate hard stops in both directions.

LA300EVK with external gate or internal operator hard stops in both directions.

4.1 Installation with external gate hard stops: (gate hard stops already installed):

a. For LA250EVK: pull out the tube completely and make 1 complete turn of the tube in clockwise direction see (picture 4.1.a).

For LA300EVK (with internal operator hard stops removed): pull the operator trolley to the max. closed position leaving 25 mm free space from absolute end position.

(see picture 4.1.a).

b. Connect the operator arm with the gate leaf bracket (see picture 4.1.b or 4.1.c).

c.

Preliminary fix the gate bracket on the gate leaf. Ensure that the gate touches the external hard stop. Consider the dimensions A and B from Table 1.

d.

Manually open and close the gate to the required positions. Ensure the operator arm does not bind and gate is moving smoothly.

For LA300EVK please ensure that in the OPEN position the trolley is having min. 25 mm free space.

e. Make permanent connection of the gate bracket at chosen correct position.

4.2 Installation with internal operator hard stops, LA300EVK only: (no gate hard stops installed):

a.

Release the CLOSE position hard stop and bring it to the required position within available range. Fix it.

b. Manually move the trolley to the hard stop.

c. Connect the gate leaf bracket to the trolley of the operator (see picture 4.1.c).

d. Make a preliminary connection of the gate bracket to the gate leaf. Ensure the gate leaf does not change its position.

e.

Manually move the gate leaf to the OPEN position and if no obstruction release the OPEN position hard stop and move it until it hits the trolley and fix it.

If there is an obstruction during manual movement, please check the A, B and C dimensions from the Table 1 and make required corrections.

f.

Once the required positions are defined make permanent connection of the gate bracket at chosen correct position.

4.3 A combination of operator and gate hard stops is allowed for LA300EVK. Please use the respective set up procedures as described above.

5. Repeat the procedure for the unit on the opposite side.

Level

5.3 Post Bracket Installation

NOTE:

For brick or concrete posts please use correct dowels and screws. Please maintain correct distance to the post edges. For metal posts please consider the post thickness and weld or

bolt the bracket directly to post. For timber posts please use correct screws and if required use reinforcement plates.

Caution:

The fastened brackets must not loosen after installation and during operation.

1

1

LA250EVK

LA300EVK

LA250EVK

LA300EVK

5. MECHANICAL INSTALLATION