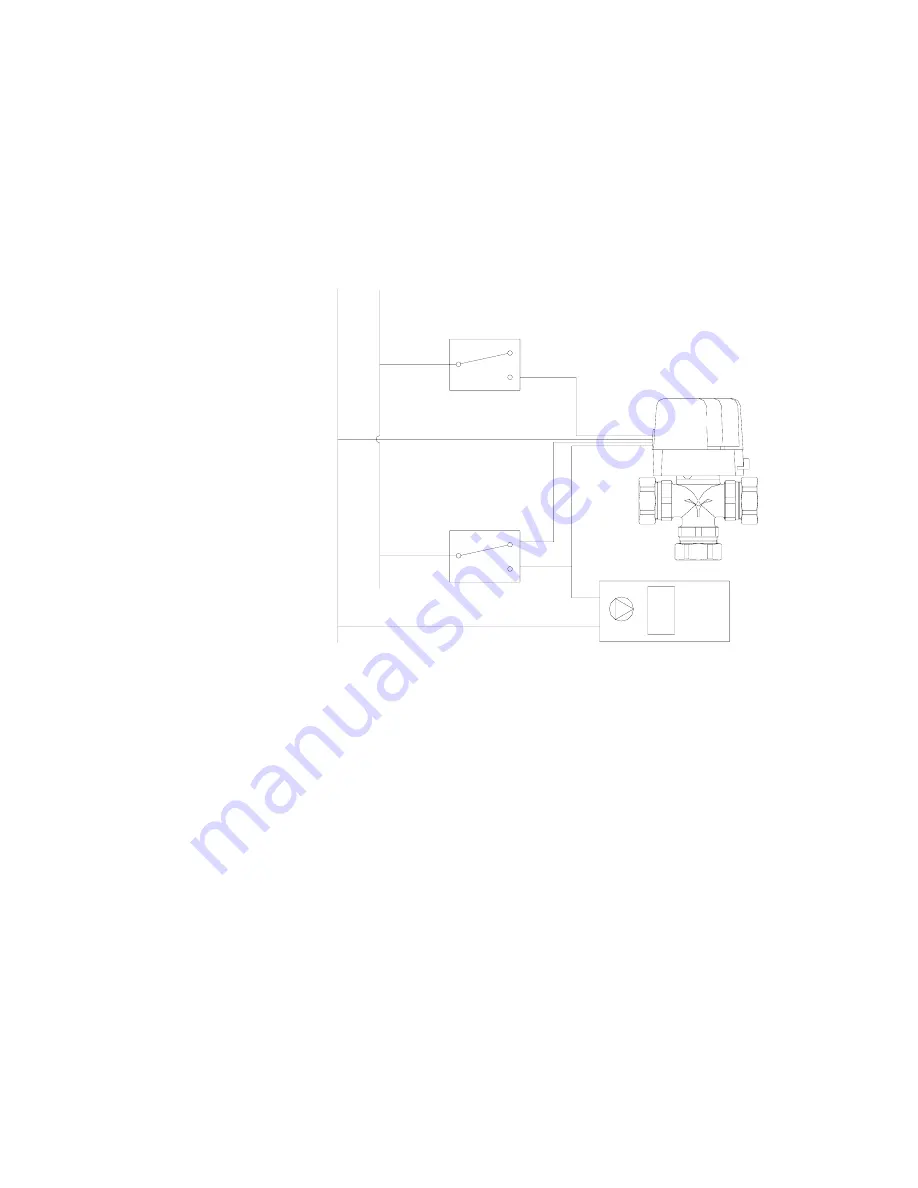

Step 4. Electrical Connections:

The actuator is fitted with 1100mm of 4-core cable for connection of the system

equipment. The installation will be simplified by the use of an electrical junction box into

which all the system equipment can connect.

The actual wiring connections will depend on the system equipment used, following the

wiring principle outlined below.

The MPE 322 is double insulated and requires no earth

connection.

IMPORTANT:

The

wiring must comply with

current I.E.E.

regulations. Ensure

mains supply to all

controls is fused at no

more than 3A. Mains

isolating switch must

have contact separation

of at least 3mm.

Step 5. Commissioning:

When the installation is complete, filled and vented, check that the valve operates

correctly.

Switch on the Hot Water Controls, i.e. programmer and cylinder thermostat: the valve

should remain at Port B with the DHW neon lighting.

MPE 322

B

AB

A

System Controls To Be FUSED 3A MAX

C.H. CONTROLS

OFF

ON

BLUE

D.H.W. CONTROLS

WHITE

ORANGE

GR

E

Y

PUMP

BOILER

N

L

ON

OFF

Switch on the Heating controls, i.e. programmer and room thermostat: the valve should

move to the MID position i.e. both outlet ports open and both neons lighting.

Switch off the Hot Water controls, the valve should move to open Port A only with the

CH neon lighting.

Notes:

a.

Ensure that the actuator is not covered with thermal insulation, or in contact with

pipe work or other materials.

b.

When the valve is fitted in confined space, ample ventilation must be provided to

ensure that the valve is kept within the specified ambient temperature range.

c.

The valve actuator is not designed for continuously powered operation.