14

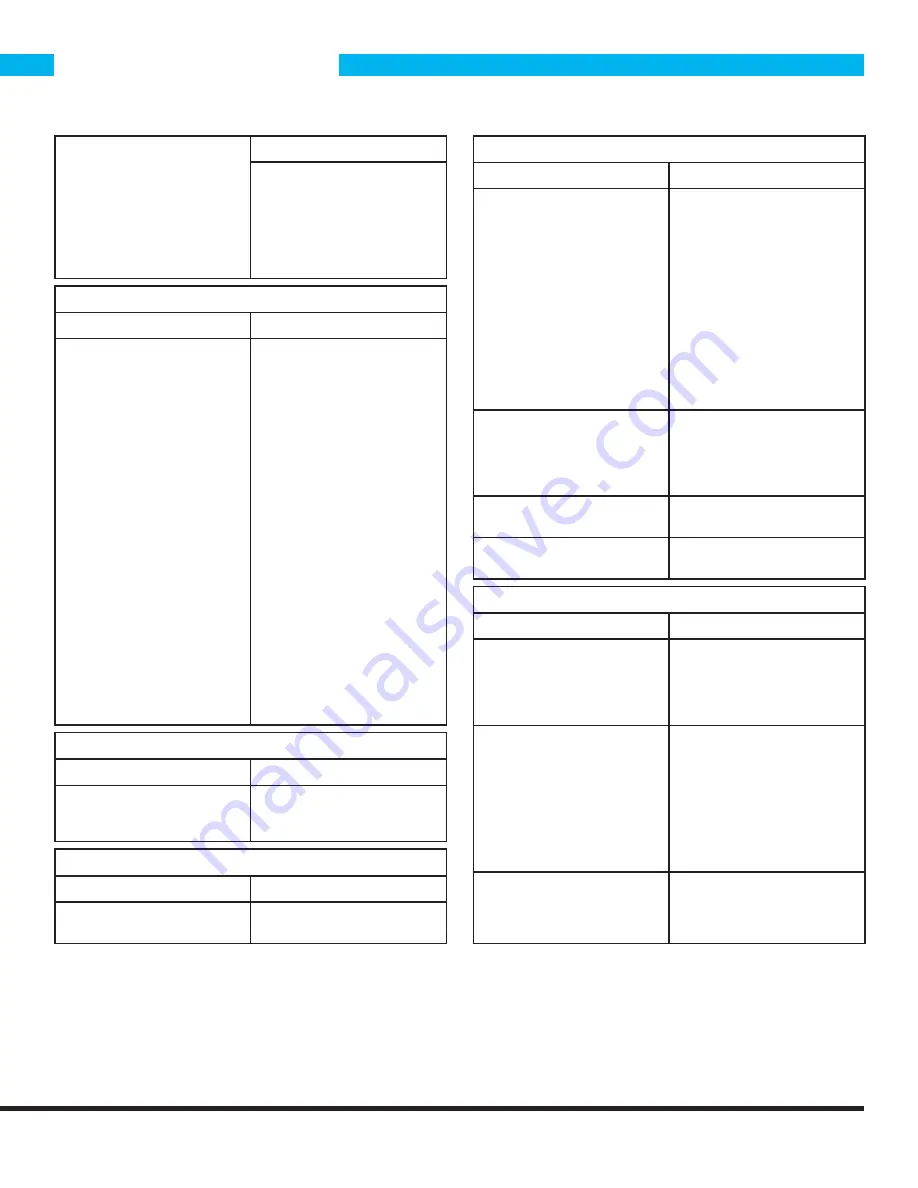

5 - Troubleshooting

Air is in the pump.

Prime the pump.

Remove QD off the ma-

chine and solution hose.

Make sure that the three-

prong clip on the inside of

the threaded end is evenly

aligned below the thread

of the QD.

Pump runs but there is no spray.

Possible Causes

Solutions

On a new unit, the check

valve between the pump

and heater may hang up,

causing the flow of water

to be impeded or stop

entirely.

Remove the check valve

temporarily and check to

see if the pump will flow

water out of the pump out-

let hose when the pump is

turned on for a brief instant

in order to verify cause.

The remedy is to install a

new check valve. Observe

the proper orientation (flow

direction) of the check

valve.

Tip: the check valve may

be able to be temporari-

ly returned to service by

un-sticking the check valve

poppet with manipulation

of the poppet ball with a

thin tool, like a straight-

ened paperclip. Replace

the check valve in unit

assembly.

NEVER OPERATE A UNIT

WITHOUT A CHECK

VALVE IN PLACE.

Pump runs for a second then shuts down.

Possible Causes

Solutions

QD is pressure locked.

Relieve pressure from be-

hind the QD by pressing in

the button inside the QD.

Low PSI.

Possible Causes

Solutions

The jet nozzle could be too

large.

Replace the jet with one

that has a smaller opening.

Pump doesn’t stop running.

Possible Causes

Solutions

Leak somewhere in the

line.

Disconnect the solution

hose from the machine.

If this causes the pump

to stop running then the

problem is outside the ma-

chine, either in the solution

hose or tool. If it continues

running on, open the ma-

chine and check for leaks.

Repair the leak. If there are

no leaks, run Mytee’s Sys-

tem Maintainer™ (Part #

3601) through the machine

to clear blockages.

Cracks or vacuum leaks on

inlet side of pump.

Make sure hoses are

secured tightly. If the

inlet side of the pump

is cracked or damaged,

replace the pump.

Seals have been degraded

by chemical.

Install seal repair kit.

Debris blocking inlet filter

or pump head.

Clean filter and/or pump

head.

Pump trips circuit breaker when turned on.

Possible Causes

Solutions

Short in power switch.

Test by swapping vacuum

and pump switch. If prob-

lem resolves, but vacuum

begins tripping breaker, re-

place switch (Part #E515).

Short in electrical harness. Risk of electric shock.

Do this at your own risk.

Remove pump from circuit

by attaching power leads

together. If breaker still

pops when switch is tog-

gled, then there is a short

to the ground in the circuit.

Replace wires as needed.

Short in pump motor.

If switch and harness

check is OK, the short

may be in the pump motor.

Replace pump.