15

5 - Troubleshooting

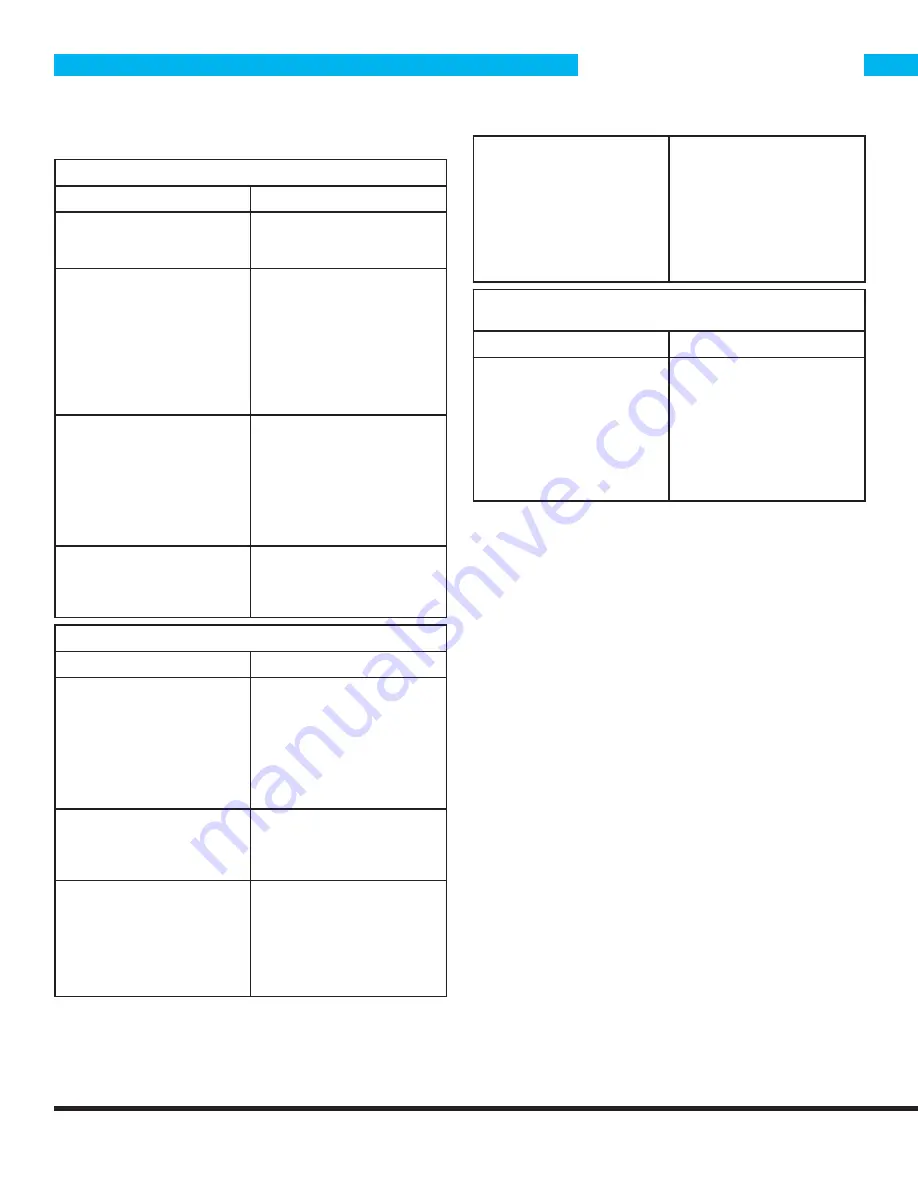

5.3 - Heater Troubleshooting

Heater is not heating water.

Possible Causes

Solutions

Loose electrical connec-

tion.

Check all electrical con-

nections, including power

cord and harness.

Automatic sensor has

failed, causing manual

sensor to trip.

Reset the manual sensor

button by pressing the

small white and yellow

button in the center of the

sensor. If this works, but

heater continues to trip the

manual sensor, replace

the automatic sensor (Part

#E573) on the heater.

Heater element has failed. Check for continuity

through the element by

reading the amperage. If

amps are low, only part of

the element may be heat-

ing up – in this case, the

element is damaged and

needs to be replaced.

Bad power switch.

If the element, sensors,

and wiring all check out

okay, there may be a bad

switch on the switch-plate.

Running out of hot water too fast.

Possible Causes

Solutions

Too much water flowing

through the heater.

Remember, when using

your machine, it is rec-

ommended you do one

wet pass followed by two

dry passes. This way you

are not spraying as much

and the hot water will last

longer.

Jets being used are too

large.

If your machine has a

1,000W or 1,200W heating

system, make sure your

cleaning tool has 0.02 jets.

Water in tank is very cold. If possible, fill your solu-

tion tank with warm water

in order to shorten the

amount of time it takes for

the water to heat up. The

pumps are usually rated

for 140°F water.

Heater has hard water

buildup inside, leading to

lost efficiency.

Run Mytee System Main-

tainer™ (Part # 3601)

through the machine regu-

larly in order to clear hard

water or chemical residue

that can block water flow

and reduce heating ability.

See product label for in-

structions.

Unit has vapor locked and there is no water pump-

ing out of the unit.

Possible Cause

Solution

Turning on the heater be-

fore turning on the pump

and priming the unit.

Turn off the heater and

allow the unit to cool

completely. When machine

has cooled, turn on the

pump first. Prime the unit

by spraying solution out

of the cleaning tool. Then,

turn on the heater.