10

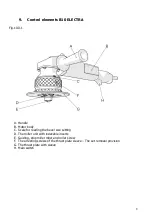

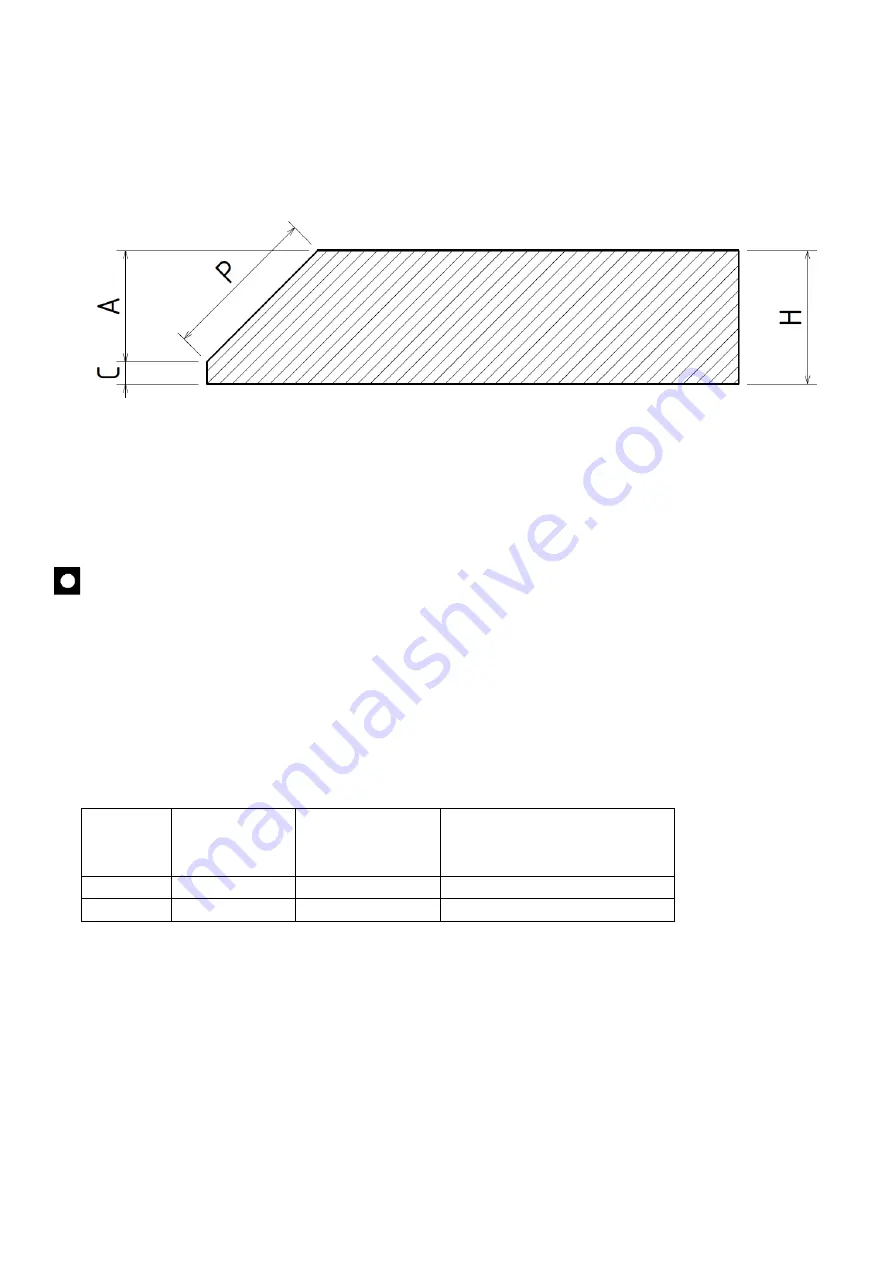

Fig. 11.1.1

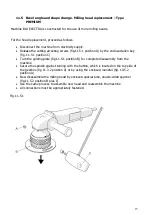

For orientation setting of the reduction size and the independent machining process, use

the setting tables for individual bevel angles.

Important:

The values in the table are calculated from point 0. Point is the point when the

miller touches the material edge for the first time. This point can be set by

gradual turning of the thrust plate (fig.10.0.1 position G) and placing to the

material edge.

45° -

For full bevel (P=10mm) is required, turn the thrust plate by 40 revolutions

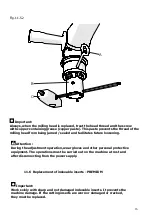

Chip no.

Hypotenuse

P

Bevel height

A

Number of rpm of the

thrust plate

(Fig.10.0.1 pos. G)

I.

5mm/0,19 in

3.5mm/0,13 in

2 Revolutions

II.

10mm/0,39 in

7.7mm/0,30 in

+ 2 Revolutions