6

6.

Safety regulations

Attention :

In order to prevent the injury observe the below instructions

Inspect the machine for mechanical and other damage prior to bevelling.

Commission the machine solely if the electricity supply cable is not damaged.

Check the supply cord regularly. In case of damage have it replaced in an authorised

service shop authorised to perform the such repairs. Contact your supplier.

Personal protection from injury

During the work use safety goggles, solid work footwear, hearing protection, suitable

head cover, e.g. safety helmet.

•

Connect the machine in electrical network solely if the machine is in off position.

•

Prior to each use, check the device and electricity supply cord for damage. Do not

use the machine in case of any damage.

•

Do not use the machine in humid environment and protect from high moisture.

•

Ensure good lighting at the workplace to prevent the risk of potential injury or

eyesight damage.

•

Caution, the tool (milling machine) is sharp with the risk of injury. During the

replacement use safety gloves,

never touch the miller which moves.

•

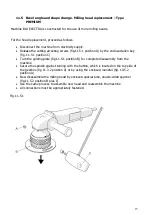

The machined material must always be fastened and horizontal. Optimum

workpiece height is 900 mm above ground.

•

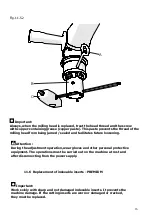

During work pay attention to the electricity supply cable; it should be loosely placed on

the ground outside the worked material and other sharp objects.

•

After work, disconnect equipment from the electricity supply.

•

Do not overload the machine motor. The machine operates better if not overloaded.

•

During work, hold the device by both hands.

•

Attention is drawn to the injury hazard with hot metal shavings.

Important:

In case of damage have the machine repaired in an authorised service shop authorised

to perform the repairs. For more information on, contact your supplier.