The oNeTRAK Manual

The oNeTRAK Manual

OPERATIONAL TIPS

12

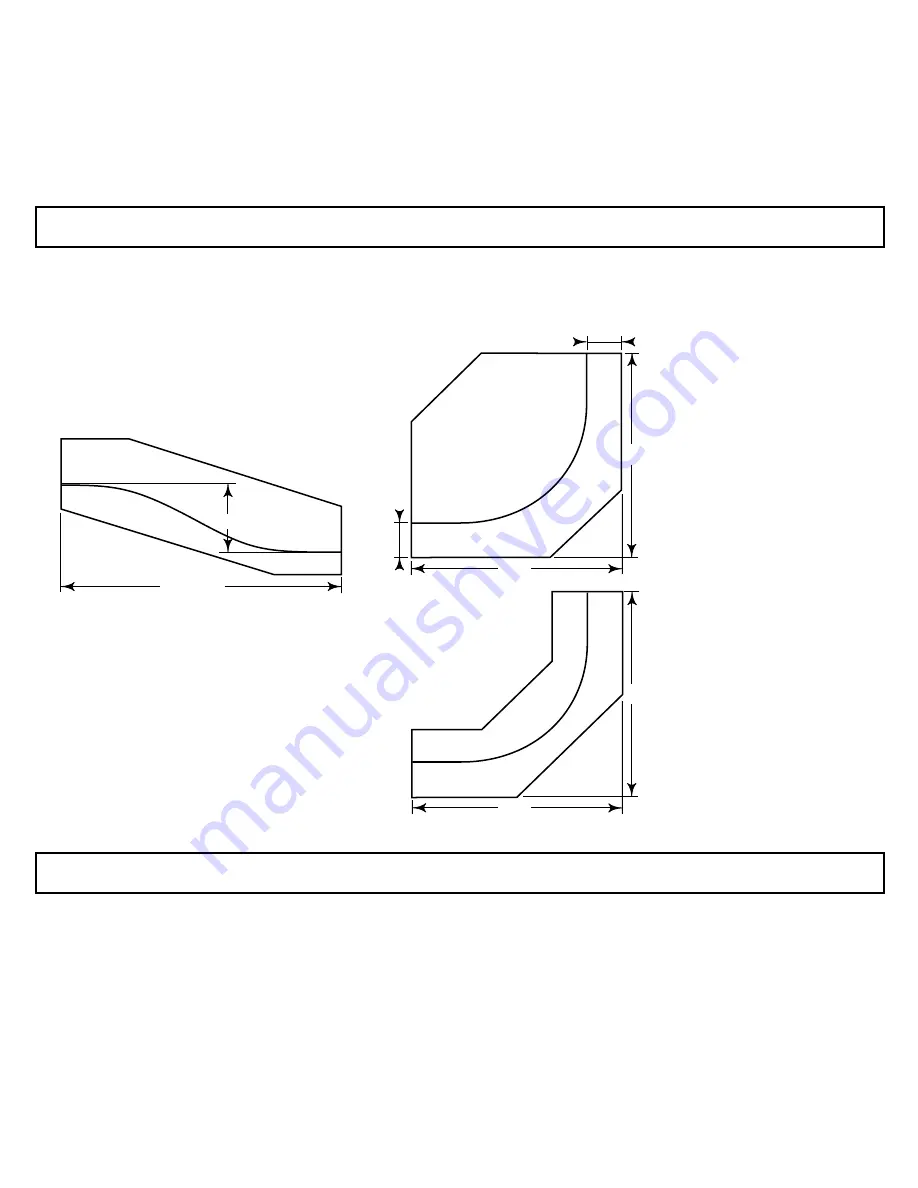

OFFSET AND CORNER MODULES

5

Multiple of 1'

4', 5' or 6'

multiple of 1'

36"

36"

36"

36"

6"

6"

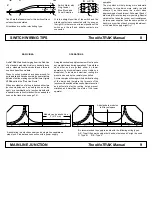

Offset modules add variety to the look of a layout.

They will not cause operational rough spots if the

minimum radius, easements, and a minimum dis-

tance between curves are considered and followed

while doing the trackwork.

When a oNeTRAK layout is designed to close a loop

special care must be taken to stay with the one-foot grid

while building modules. This is especially true with odd

shaped or junction modules. When there's no intention to

close a loop in the near future, there might be one later...

Corners might be used as inside or outside corners.

While the dimensional problem can be simplified by

sticking to the 6" grid, the electrical connection for both

uses can be prepared by providing two connectors on

each side, male and female. The polarity of the second

set must be switched in order to be right when the

module is used with the "wrong" side.

Corner modules may be built as

3'x3' or 4'x4'. Minimum radius must

be kept and while bigger modules

tend to be heavier and more difficult

to transport, a curve with larger

radius will always look better.

It is possible to cut out parts of the

corner module in order to reduce its

weight and space consumption.

Special care then must be taken to

leave enough strength and stiffness

to prevent damage while clamping

together the layout!

A 4'x4' version of this design will

need a stiffer frame, the reduction in

size and weight is still remarkable

compared with a conventional form

(as seen above).

1.

Try to get longer sidings for operating flexibility.

A switching scheme can be made up with a 6'

maximum train length, but longer sidings with

industries spread around make operations more

interesting and planning them more flexible.

2.

Test out modules ahead of time. It's far too late

to find a short circuit in your track work when the

modules are to be clamped together at a Show! To

be sure that all modules work flawlessly it's a good

idea to have a test set up with all new or rebuilt

modules. Don't forget to check all sidings and

spurs.

3.

The planning of an operating scheme needs

as much preparation as the planning of the layout

itself. Special care should be taken to meet the

expectations of the attending operators. An all-

digital or all-analog layout is only a valid option if

everybody agrees on doing so. The same applies

to an all switching layout. The key idea for most

cases is to have the layout split up into a digital and

an analog district, and into portions with trains

looping and others with local switchers at work.

4.

When car switching operation is desired, car

cards or switching lists need to be made up in

advance. A car pool must be collected and it must

be certain that selected cars show up. For smaller

schemes it is a good idea that the one preparing

the switching operation uses his own cars

exclusively.

5.

Prototypical operation needs a vast number

of people! One single engineer per train is fine

when the scheme is very simple and the engineer

has some experience. When cars are to be

switched a conductor is imperative. When the

choosen switching scheme is new to the majority

of the attendees, a three man crew will solve most

problems. Staff planning is vital for a successful

operating session. Five trains with a two man crew

makes ten people. Add a dispatcher and a

superintendent and you will need a dozen operators

to fill the callboard for one session.

6.

Name everything! As with the prototype every

location with relevance to operation needs a

specific name, preferably being unique throughout

the layout. If industries are to be served they need

names too.

7.

Make sure that you have a system to identify

the owner of all rolling stock. An easy solution is to

color code the kingpin of the cars and the underside

of the locomotives. Each member is assigned a

unique color (or combination of two colors for

larger clubs). The club keeps track of the colors

already taken.

8.

Clean the Track and Clean the Wheels. This is

good practice whether DC or DCC. The important

message in this rule is to be sure that the track has

dried from any liquid track cleaner (such as Goo

Gone or 409) and that any residue has been

removed. If trains are run while the track is still wet,

then the train will spread any dirt that is coming off

wheels or the residue of the cleaner all over the

layout. Then you have a real problem. There are

two ways to clean the track - use two Centerline

cars with a wet cloth on the front roller and a dry

cloth on the rear roller, or wipe the track with a wet

rag or Q-tip then follow up with a dry rag. Clean

wheel sets with a paper towel laid on a track and

wetted with Goo Gone or 409. Roll the car back

and forth and the gunk will come off. For

locomotives, do one truck at a time on the towel

with power applied so the wheels are turning.