5 of 8

www.NabcoEntrances.com

GT1505BumpOutConvenienceWindowInstallationManual

Rev. 12-15-17

P/N C-00208

DN 1822

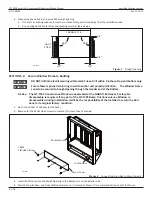

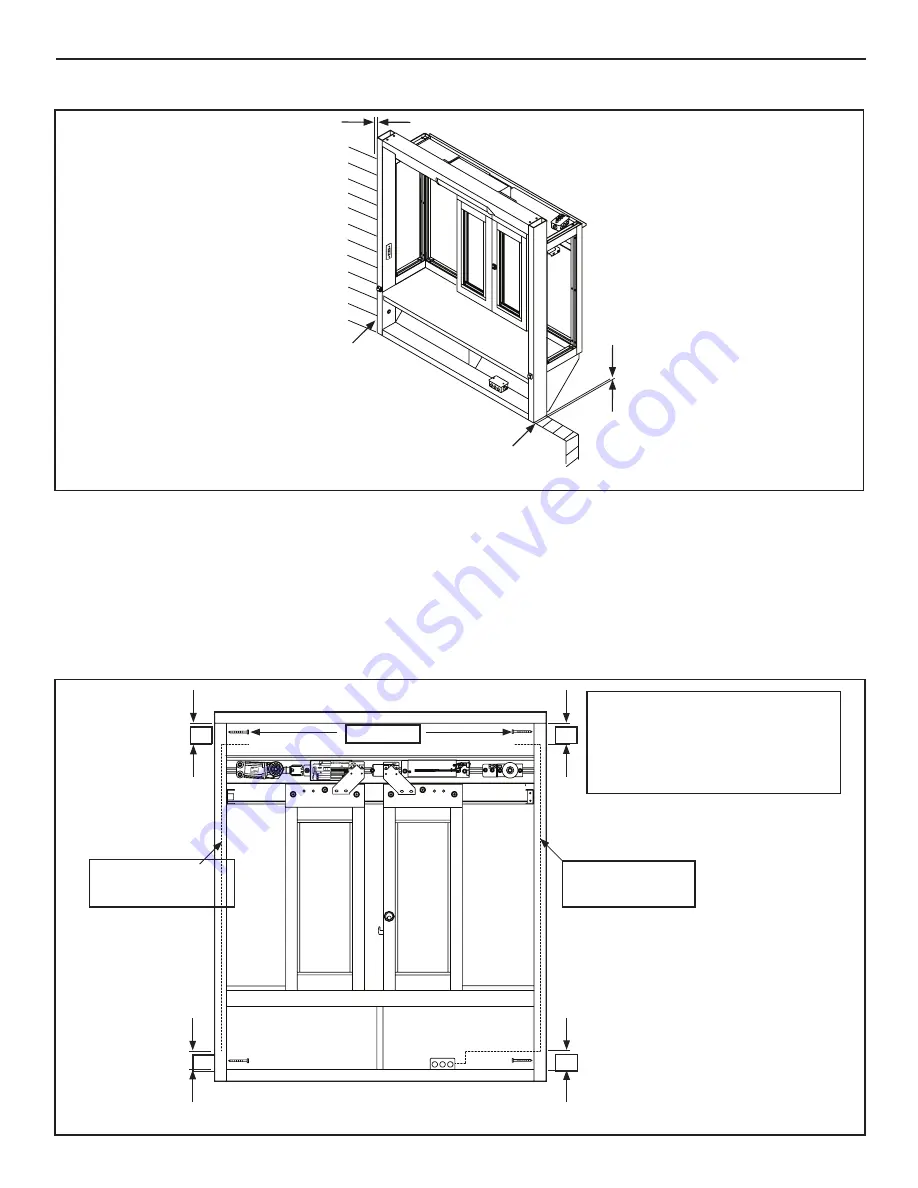

1/4" Shim and plumb

for proper clearance

OUTSIDE OF BUILDING

INSIDE OF BUILDING

Rough Opening

1/4" Shim and plumb

for proper clearance

Rough Opening

Figure 3

Shim and Plumb Window Frame

5. Mark and drill a minimum of (2), 1/4 inch diameter screw holes (within 3 inches) from the top and bottom in each Jamb Tube.

a. It is recommended to countersink each screw hole.

b. Use an appropriate tap drill to drill a pilot hole.

6. Secure Jamb Tubes with 1/4 inch diameter screws.

a. Fasteners are not provided by NABCO.

b. Ensure each visible screw head is flush on face of Jamb Tube.

c. Do not overtighten fasteners to prevent deforming the Jamb Tube.

7. Apply a caulking bead between the Window Unit and Rough Opening (inside and outside).

NABCO

24-11493

GYRO TECH

DS-150

NA

(

24-11327

)

MADE IN JAPAN

5 6

Sequential Activation

SQ

Auxiliary Output (Open-Collector)

5Amax.(0-20V), 3.2Amax.(20-30V)

30V(42.4Vpeak)max.

Contact Output (Class2 Load only)

N/C

N/O

12VDC-(Common)

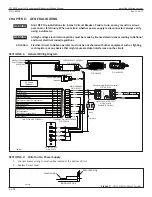

FUNCTION [SLIDING DOOR]

SYMBOL No.

Reduced Opening Switch

7

6

5

4

3

2

1

Breakout Detector

Sidelite Presence Sensor

Exterior Activation

BA

62

M1

H

M0

Holding Beam

Interior Activation

12VDC-(Common)

12VDC+

6B

9DC12V

7

61

Mode Switch (see Mode SW Usage shown left)

HANDY TERMINAL

・

6P

To protect against risk of

fire

or electric shock,use only the

certified NABCO power supply.

WARNING

No.

MOTOR

・

12P

ERROR

POWER

BA

62

H

6B

61

IN

DI

CA

TO

RS

PO

W

ER

・

2P

Do not disassemble the control box.

There are no user serviceable parts

inside.

To maintain warranty,repairs must be

made by authorized NABCO facilities.

CAUTION

Adjustments to the door can only be made

with the NABCO Handy Terminal.

Mode SW Usage

Gnd

Gnd

Gnd

Open

Open

Open

Gnd

Open

M0

M1

MODE

TWO WAY

ONE WAY

NIGHT

HOLD OPEN

248901-

Microprocessor Controller

20

VA

C

50

/60

Hz

GYRO TECH

NABCO

24-11493

DN 1821

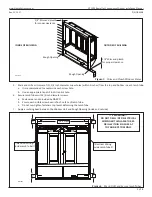

1/4” Screw

!!Electrical Wiring

inside Jamb Tube!!!

!!Electrical Wiring

inside Jamb Tube!!!

3”

3”

3”

3”

!! !! WARNING !!

DO NOT DRILL INTO ELECTRICAL

WIRING WITHIN JAMB TUBES.

DRILL WITHIN 3 INCHES AT

TOP AND BOTTOM ONLY.

Figure 4

Mark, Drill, and Secure Jamb Tubes