63

NABRICO DF-1 N ELECTRIC WINCH Owner’s Manual

OM-DF1-021-A

MOTOR BRAKES

INSTALLATION & MAINTENANCE

RETAIN FOR FUTURE USE

U35000 - 9 of 19

www.nord.com/docs

06.13.16

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378

Brake Rotor (Brake Disc) Wear Assessment

Periodically the brake rotor or brake disc must also be checked

for wear. If the brake rotors wear approaches the minimum

allowed thickness, then the part should be replaced. Use

Table 7 to determine whether or not the brake rotor requires

replacement.

Table 7: Brake Rotor Thickness

Brake Size

Nominal Brake Rotor

Thickness

Minimum Brake Rotor

Thickness

[in]

[mm]

[in]

[mm]

BRE 5

0.295

7.5

0.177

4.5

BRE10

0.335

8.5

0.217

5.5

BRE20

0.406

10.3

0.295

7.5

BRE40

0.492

12.5

0.374

9.5

BRE60

0.571

14.5

0.453

11.5

BRE100

0.630

16

0.492

12.5

BRE150

0.709

18

0.571

14.5

BRE250

0.787

20

0.650

16.5

BRE400

0.787

20

0.650

16.5

BRE800

0.787

20

0.650

16.5

BRE1200

0.866

22

0.689

17.5

As new condition.

Worn condition - brake rotor replacement is required!

Brake Pad Replacement

(reference to parts list on page 8)

When the brake pad is worn the pad should be replaced to

maintain proper brake operation and ensure safety.

Required Tools

• Phillips head screw drivers (fan shroud removal)

• External snap ring pliers (fan and brake hub removal).

• Large flat head screw driver or small pry bar (fan removal)

• Metric T-handle wrenches and open-end wrenches.

Procedure

1. Remove the fixing screws (946) securing the fan cover (940)

to the motor end-shield (932). If the brake has a hand

release (937), the lever arm should be removed by

unscrewing it.

2. Remove the fan cover (940) and note the position of the

hand release slot if applicable.

3. Remove the snap ring holding the cooling fan (939) and

carefully remove the cooling fan (939), key and second

snap ring (997).

4. If the brake is equipped with a dust boot (992), remove it.

5. Remove the socket head cap screws holding the brake coil

(936) to the motor end-shield (932).

6. Remove the brake coil (936), noting the hand release (937)

and power cable locations.

7. Slide the brake rotor (993) off the brake hub (938) which is

secured to the motor shaft.

8. Clean the brake, install the new brake rotor pad and

reassemble the brake in reverse order of the steps outlined.

Optional Brake Accessories

NORD can supply a variety of brake options and accessories,

of which some of the most common are noted below.

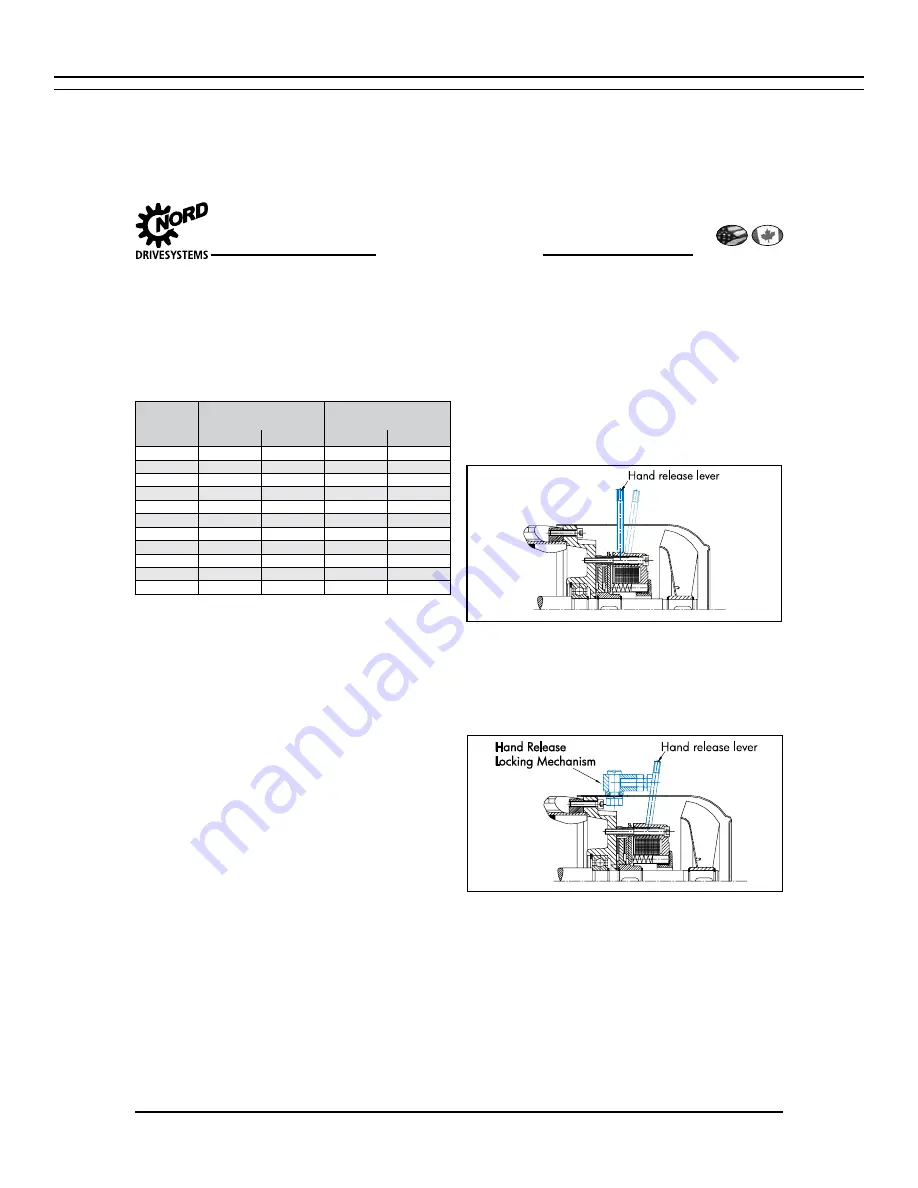

Hand Release Lever (HL)

The hand release lever allows the brake to be manually re-

leased without requiring that the brake be energized with

voltage. The lever has a spring return that allows the brake to

be hand released and returned automatically to its set posi-

tion. The handle of the hand release lever can be unscrewed

for easy removal.

Figure 8

Por Palanca de Liberación

Locking Hand Release Lever (FHL)

This option allows the brake to be manually released and

locked off without requiring voltage to the brake. The lock

mechanism prevents the spring from returning the brake to

a closed state without manual action by the user. The hand

release lever can be unscrewed for easy removal.

Figure 9

Por Palanca de Liberación

Liberación de mano

de mecanismo de

bloqueo

Corrosion Protected Brake (RG)

The brake is fitted with a stainless steel brake plate to pro-

vide additional corrosion protection in severe and wet envi-

ronments.

Dust & Corrosion Protected Brake (SR)

A rubber-sealing boot is installed on the brake to provide

additional protection in dusty environments. This feature in-

cludes the stainless steel brake plate (RG).

IP66 Brake (IP66)

NORD can also provide an IP66 brake option designed for

a bigger degree of protection against severe environments.

Summary of Contents for DF-1 N Series

Page 1: ...OM DF1 021 A NABRICO DF 1 N Electric Winch Owner s Manual ...

Page 2: ...THIS PAGE IS INTENTIONALLY LEFT BLANK ...

Page 21: ...21 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 22: ...22 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 23: ...23 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 25: ... A 25 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 26: ... 72 61 26 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 27: ... 1 1 2 3 Ω 27 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 28: ... 63 2 M4 Attachment 28 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 29: ... 1 1 1 1 1 1 2 2 2 2 29 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 31: ... 31 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 32: ... 1 1 1 1 2 2 2 2 3 3 3 3 32 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 36: ...36 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 69: ...69 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...

Page 70: ...70 NABRICO DF 1 N ELECTRIC WINCH Owner s Manual OM DF1 021 A ...