59

NABRICO DF-1 ND ELECTRIC WINCH Owner’s Manual

OM-DF1-017-G

D.3 GEARMOTOR TECHNICAL INFORMATION (FLANGE MOUNTED)

REDUCER MOUNTING

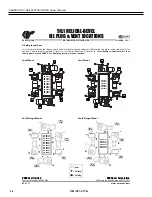

FOOTED & FLANGE MOUNT GEAR UNITS

RETAIN FOR FUTURE USE

U10500 - 1 of 2

1. Foot-mounted reducers

When installing the foot-mounted gear unit, observe the

flatness specifications and bolt tightening torque guidelines

provided in U10060 and make sure the mating mounting

surface and reducer feet are clean and free of debris. Use

of shims under the feet of the gear unit may be required in

order to align the output shaft to the driven equipment.

Make sure that all feet are supported so that the housing

will not distort when it is bolted down. Improper shimming

will cause mis-alignment and may reduce the life of the gear

unit or cause component failure. Dowel pins may be field-

installed to help prevent misalignment and ensure proper

realignment if removed for service.

IMPORTANT NOTE

Gear units may be subjected to radial loads or side pull,

caused by external chain drives or belt drives. In these

instances it is recommended that the mounting base be

designed with a slide-plate adjustment to accommodate

extra slack in the chain or the belt after the feet are

loosened. When using an external chain or belt drive,

make sure the reducer is sized so that the shaft and

bearings have adequate capacity.

2. Flange-mounted reducers (with B5 flange)

When using the B5 flange to mount the gear unit, the bulk

head plate must be engineered to minimize buckling distor-

tions and support the cantilevered weight of the gear reduc-

er or gearmotor. On the B5 mounting flange NORD provides

a pilot register or and the flange pilot tolerance as listed per

Table 1. When the mating hole is designed with the proper

fit, the flange pilot tenon provides a means of accurately po-

sitioning the reducer while the hold-down bolts are properly

secured; once the reducer is secured, the tenon helps prevent

movement of the reducer and it helps locate the center of

the reducer output shaft.

Table : Flange Pilot Tolerance

Above

ø (in)

To &

Including

ø (in)

Tolerance

(in)

ISO 286-2

Fit Class

1.969

3.150

+0.0005 / -0.0003

j6

3.150

4.724

+0.0005 / -0.0004

j6

4.724

7.087

+0.0006 / -0.0004

j6

7.087

9.055

+0.0006 / -0.0005

j6

9.055

9.843

+0.0000 / -0.0011

h6

9.843

12.402

+0.0000 / -0.0013

h6

12.402

15.748

+0.0000 / -0.0014

h6

15.748

19.685

+0.0000 / -0.0016

h6

19.685

21.654

+0.0000 / -0.0017

h6

Above

ø (mm)

To &

Including

ø (mm)

Tolerance

(mm)

ISO 286-2

Fit Class

50

80

+0.012 / -0.007

j6

80

120

+0.013 / -0.009

j6

120

180

+0.014 / -0.011

j6

180

230

+0.000 / -0.013

j6

230

250

+0.000 / -0.029

h6

250

315

+0.000 / -0.032

h6

315

400

+0.000 / -0.036

h6

400

500

+0.000 / -0.040

h6

500

550

+0.000 / -0.044

h6

When installing the flange mounted gear unit, observe the

flatness specifications and bolt tightening torque guidelines

provided in U10060. Make sure the mating mounting surface

and reducer flange are clean and free of debris. Use a straight

edge or parallel bar to check for high spots on the mating

mounting surface and remove any raised material around the

mounting holes.

Set the gear unit into place and tighten the bolts until they

are snug. Before final bolt-tightening check for any mate-

rial gaps between the mating surfaces and if shimming is re-

quired, use “U” shaped shims at least 2 times the width of the

bolt. Avoid over shimming a very irregular surface as this will

make it very difficult to achieve proper alignment.

IMPORTANT NOTE

For heavy shock applications, it is advisable to field-in-

stall dowel pins through the mounting flange connec-

tion (in addition to the mounting bolts). This will help

control flange movement or flange rotation and relieve

the mounting bolts from this additional stress.

www.nord.com/docs

07.19.16

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378

Summary of Contents for DF-1 Series

Page 1: ...OM DF1 017 G NABRICO DF 1 ND Electric Winch Owner s Manual ...

Page 2: ...THIS PAGE IS INTENTIONALLY LEFT BLANK ...

Page 21: ...21 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 22: ...22 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 23: ...23 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 25: ... A 25 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 26: ... 72 61 26 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 27: ... 1 1 2 3 Ω 27 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 28: ... 63 2 M4 Attachment 28 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 29: ... 1 1 1 1 1 1 2 2 2 2 29 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 31: ... 31 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 32: ... 1 1 1 1 2 2 2 2 3 3 3 3 32 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...

Page 36: ...36 NABRICO DF 1 ND ELECTRIC WINCH Owner s Manual OM DF1 017 G ...