Chapter 4 Preparations for Installation

16

Handling bolt size/Hollow shaft series

Table 4-6

Model code

Handling bolt

Nominal size × pitch

(mm)

Qty.

Weight (kg)

Straight*1

Right angle*1

Pulley

RD -010C

-

-

10 to 22

12 to 23

10

RD -027C

M6 × 1.0

4

17 to 28

18 to 30

16

RD -050C

M8 × 1.25

4

30 to 42

33 to 45

29

RD -100C

M10 × 1.5

4

38 to 50

41 to 53

37

RD -200C

M12 × 1.75

4

96 to 112

118 to 134

94

RD -320C

M12 × 1.75

4

141 to 158

164 to 180

140

*1: The weight varies depending on the coupling inner diameter of the input unit and the motor flange type.

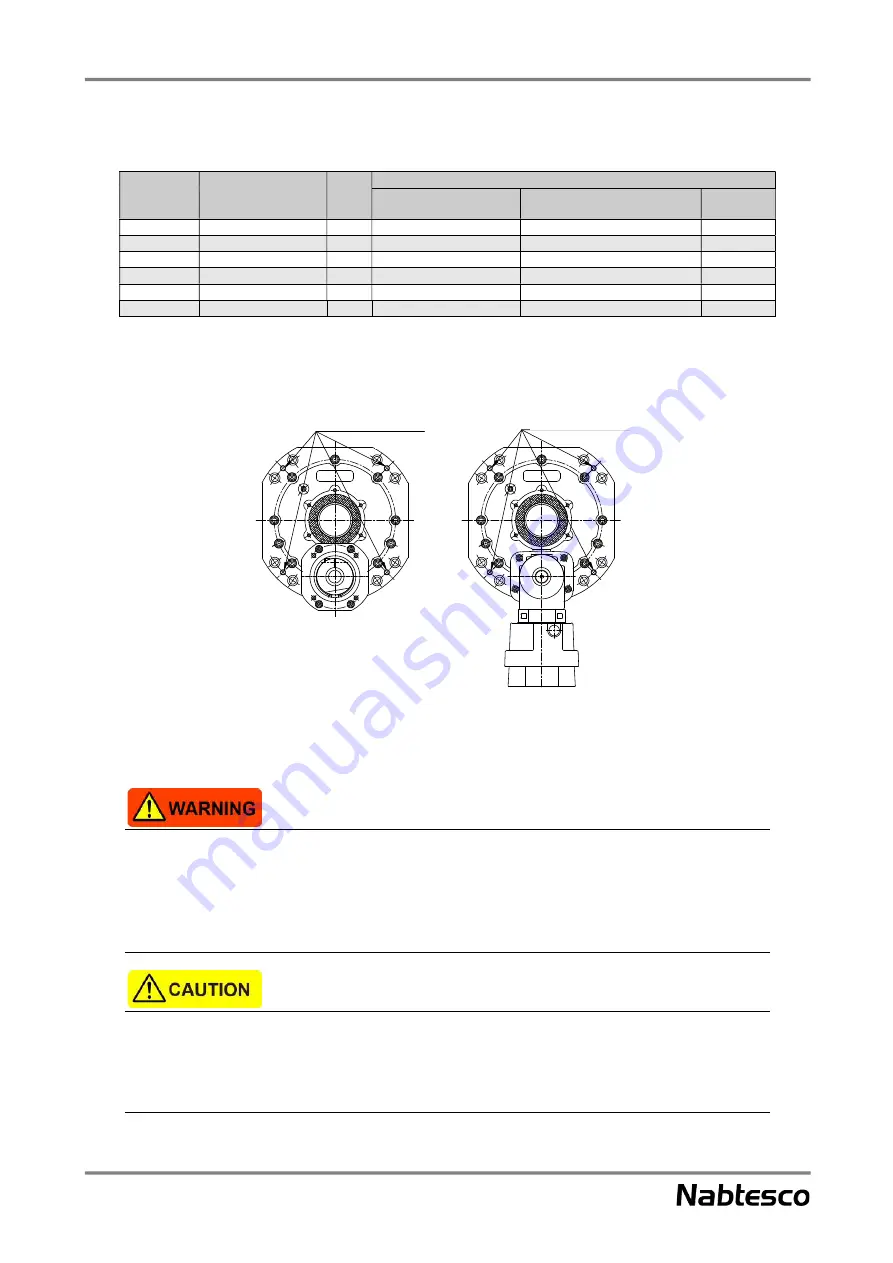

<For RD -027C, 050C, 100C, 200C, and 320C>

For the straight input type and

pulley input type

Right angle input type

Fig. 4-6

Do not enter the area under the reduction gear when lifting the reduction gear. If the reduction gear

falls down, it could cause injury.

When lifting the

reduction gear

, be sure to use a lifter that can withstand the weight of the reduction

gear. Otherwise, the lifter will be damaged, and the reduction gear could fall down and topple over,

which may result in injury.

Be sure that no load is applied to the hollow section when lifting. The reduction gear could be

damaged and the components could fall down, which may cause injury to the workers. In addition, the

oil seals for the hollow section may be deformed, which could eventually cause leakage of the

lubricant.

Tapped hole for

handling bolt

Tapped hole for

handling bolt

(4 locations)

(4 locations)